Product type: WB6P

Logistics robot for the factory

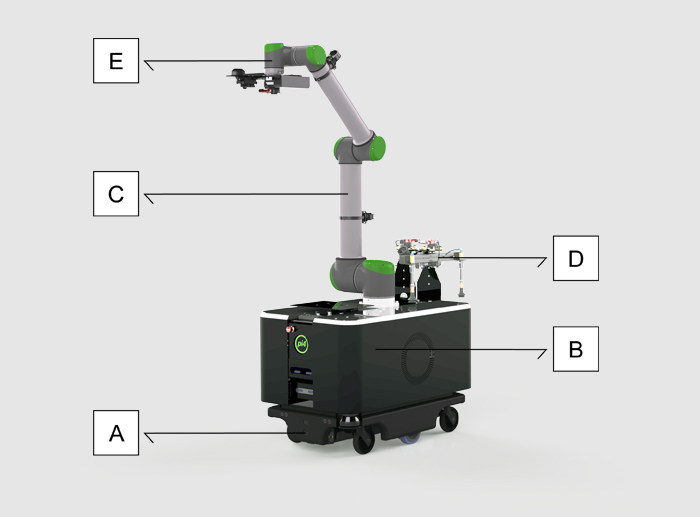

Workerbot6p - Logistics robot for the factory

With the help of the workerbot6p logistics tasks in a production can be automated. The robot can recognize parts e.g. in a tray and take them out of the tray with its gripper. A gripper station with vacuum or mechanical gripper is available for different types of parts at the back side of the robot. The gripper can be changed automatically.

| E | Gripper and 3D camera |

| D | Gripper station for different grippers |

| C | articulated arm robot |

| B | Master Control Unit, Image processing Unit, Vacuum Unit, Power Unit |

| A | Mobile robot |

The robot can idendify the part to be gripped by means of a QR code and then localize it using its 3D image processing algorithms. After selecting the appropriate gripper, the parts are automatically picked from the tray or a deposit. For transport, the robot arm is moved into a special pose and the automatic travel to the target position starts.

Features

- can move independently within the factory

- autonomous avoidance of obstacles

- orientation by means of a created digital map

- gripping of parts by vacuum suction cup or with mechanical 2- or 3-finger gripper

- automatic recognition of parts by 3D camera with image processing algorithms

- recognition of part number by QR or barcode reader

- suitable for UR3(e), UR5(e) or UR10(e) robots

- power supply via integrated rechargeable battery

- automatic battery charging at docking station