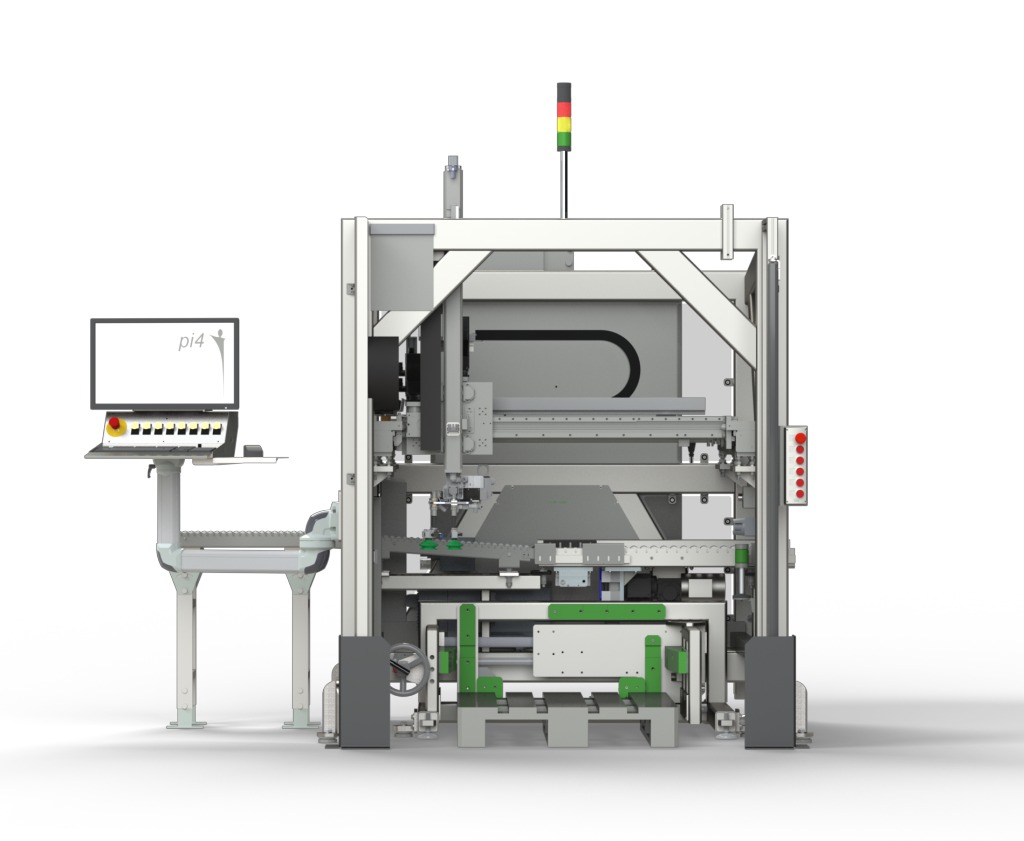

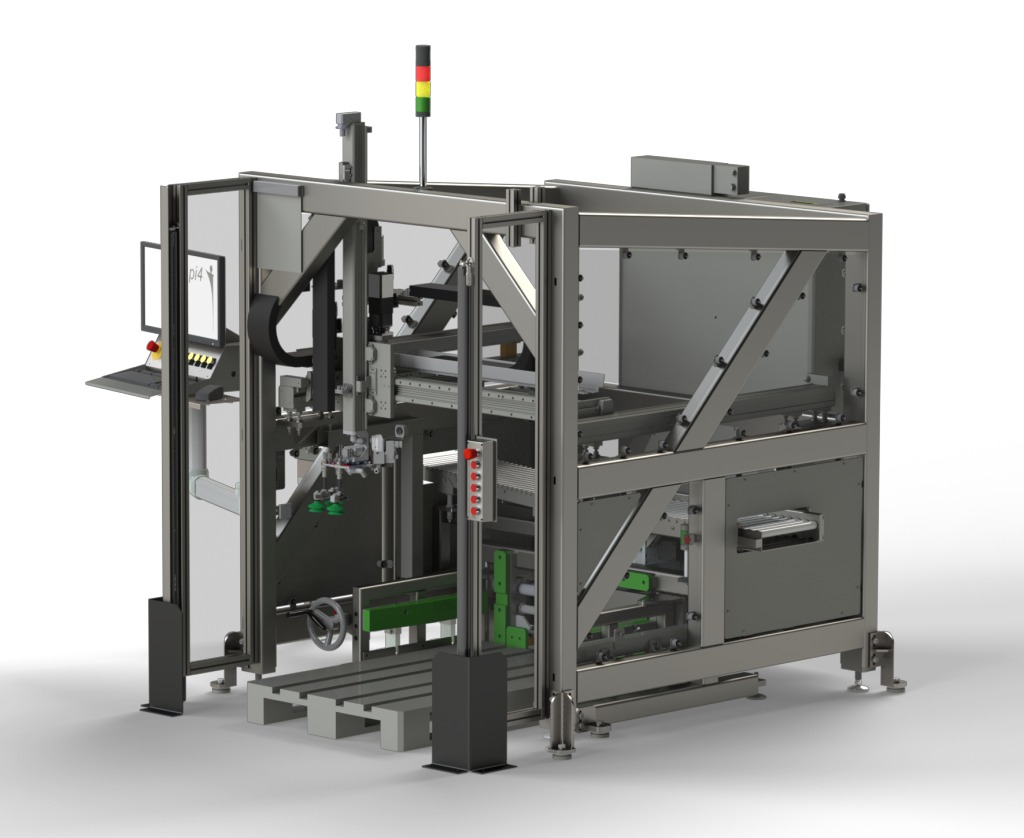

Palletizing robot PAL1

Customer benefits

- Short cycle time

- Container and pallet types freely selectable within maximum dimensions

- Layer patterns freely selectable by the operator

- Product size freely adjustable within maximum dimensions

- Stacking with different layer patterns possible

- Convenient operation with clear, structured operator guidance

- Remote maintenance via Internet

- Packing size maximum 1200x800x600 mm³

Automated production is only really efficient if the stacking of products in boxes or on pallets is also automated. Since the products can be both large and heavy, and small and very light light, flexible and intelligent solutions are necessary. The PAL1 palletizing robot offers such a solution.

The products to be processed are fed to the palletizing robot via a roller conveyor or a conveyor belt and brought into the desired pick-up position by an integrated positioning unit. From there, they are picked up by a gripper. The product is positioned at speeds of up to 1.5 m/s via the three standardized high-performance linear axes. At the same time, it can be rotated to the desired position using the robot’s rotary axis.

Any palletizing or crate packing scheme can be freely set using the pi4_control operating software. The type and size of the parts fed is irrelevant. They can be placed on pallets or in crates. The overall system is therefore highly flexible and suitable for use in various industries