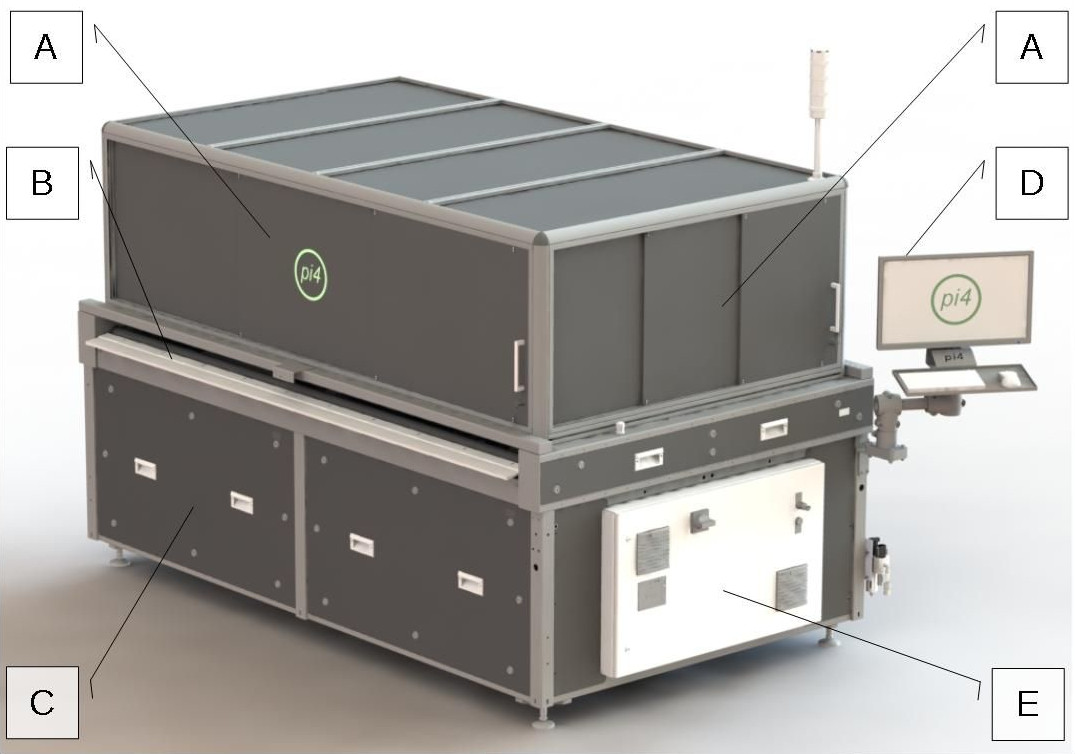

| A | Security-monitored sliding door for easy access |

| B | Automatic flap |

| C | Easily removable service covers |

| D | Operator panel |

| E | Electrical cabinet |

The Efficiency XL is an outstanding automatic test system for solar modules based on the electroluminescence process.

The module tester Efficiency XL is the consistent adaptation of the proven module tester series Efficiency to the current requirements of solar module production. Larger cells and modules, half cells and flexible module layouts are now the standard.

Fully automated and reliable failure detection on multi- and mono-crystalline cells are outstanding features. It is designed to be engaged before or after the lamination process in highly automated production lines.

In addition, a Backlight test or an Highpot test can now also be integrated as an option.

As well as offline in the laboratory, the EL Efficiency is a highly precise El inspection system.

With enhanced functionality like the AEVAL-Software (Advanced EVALuation), even the most complex quality guidelines can be implemented.

The “Power Loss Estimation” (PLE) software feature is a reliable forecast, about the maximum power loss that may be caused in future field operation by defects detected in cells today.

The pi4 “Repair Station Manager” (RSM) supports the operator effectively to replace defective cells and strings.

Advantages:

- The machine concept of in-line EL inspections systems incorporates all our 20-years experience in the area of machine engineering.

- Pi4 is an image processing specialist. We have developed a unique technology for reliable defect detection for mono and multicrystalline cells.

- Easy to use machine software.

- Secure and precise handling of modules, even unlaminated and with glass thickness down to 2 mm.

- Ambient light protection with automatic entry and exit doors.

- Precise automatic contacting of modules.

- Only high quality components from well-known manufacturers are used.

- Flexible adapting of line interfaces and machine security integration.

- Convenient and flexible access to the test data, e.g. via an implemented database.

Technical specifications:

- EL Inspection with up to 185.4 MPixel, 122μm/Pixel Resolution

- Cycle time from 18s with parallel pull-in and push-out

- Modules sizes up to 2300mm x 1200mm, sunny side down, long edge leading

- Modules pre lamination, laminated with or without frame

- Conveyor height 920 - 1050mm, up to 400mm/s

- Automatic contacting on connectors or J-boxes

- Cell sizes from M3 to M12

- Full and halfsize cells

- Mono or multicrystalline cells

- EL-Power 0-90V/0-14A

- UPS

- Signal interface to the conveyors befor and after the tester via ProfiBus, ProfiNet, digital I/O etc

- MES connection via database

- Signal interface to a higher-level safety control

- Power supply 380-400V AC 50-60Hz TN-S-System

- Compressed air 6 bar

- Machine frame 2680mm x 1600mm

Options:

- Code reader

- Backlight Inspection

- PE conductor, insulation and high voltage test

- Accessories for offline use

- Software “AEVAL”

- Software “Power Loss Estimation”

- Software “Repair Station Manager”