Robofeeder-MC - Separation, inspection and feeding of parts

Customer benefits

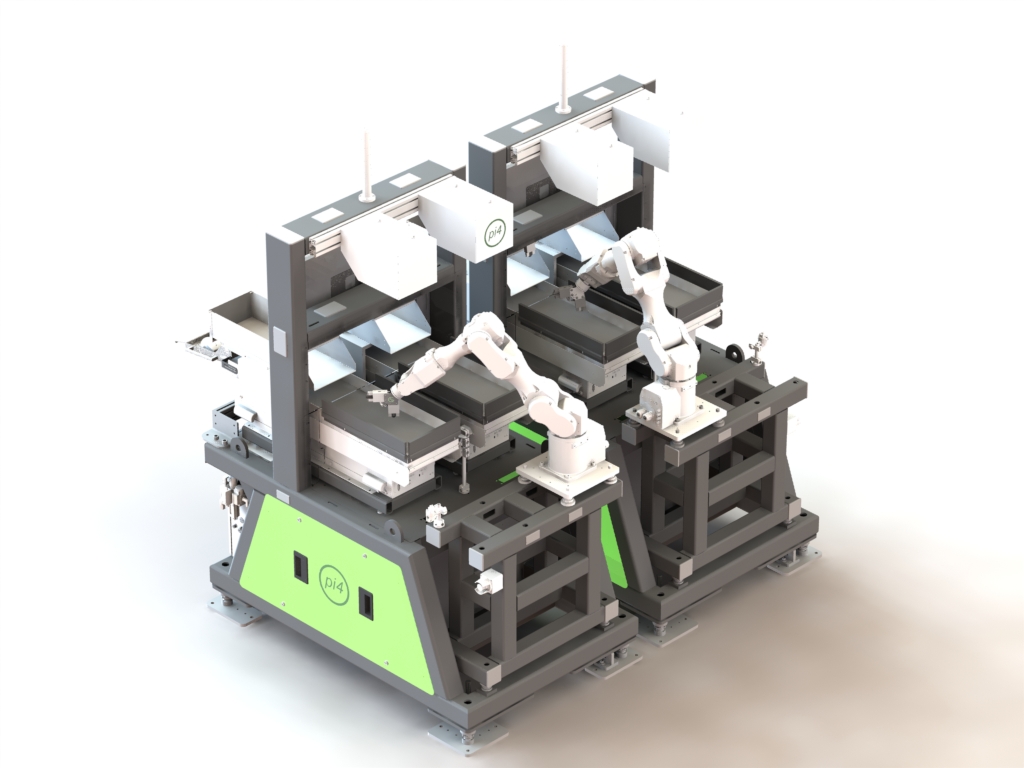

- Independent provision of parts over several hours

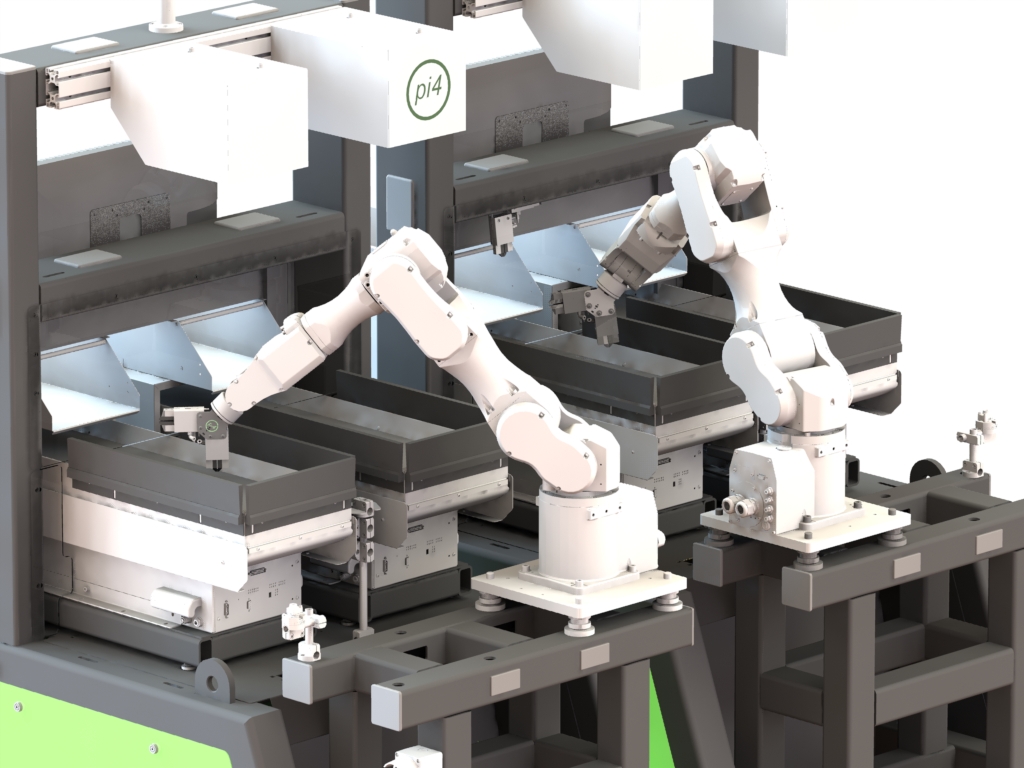

- Separation of parts by oscillating motion

- Inspection of user-defined features with camera systems

- Feeding of good parts 24/7

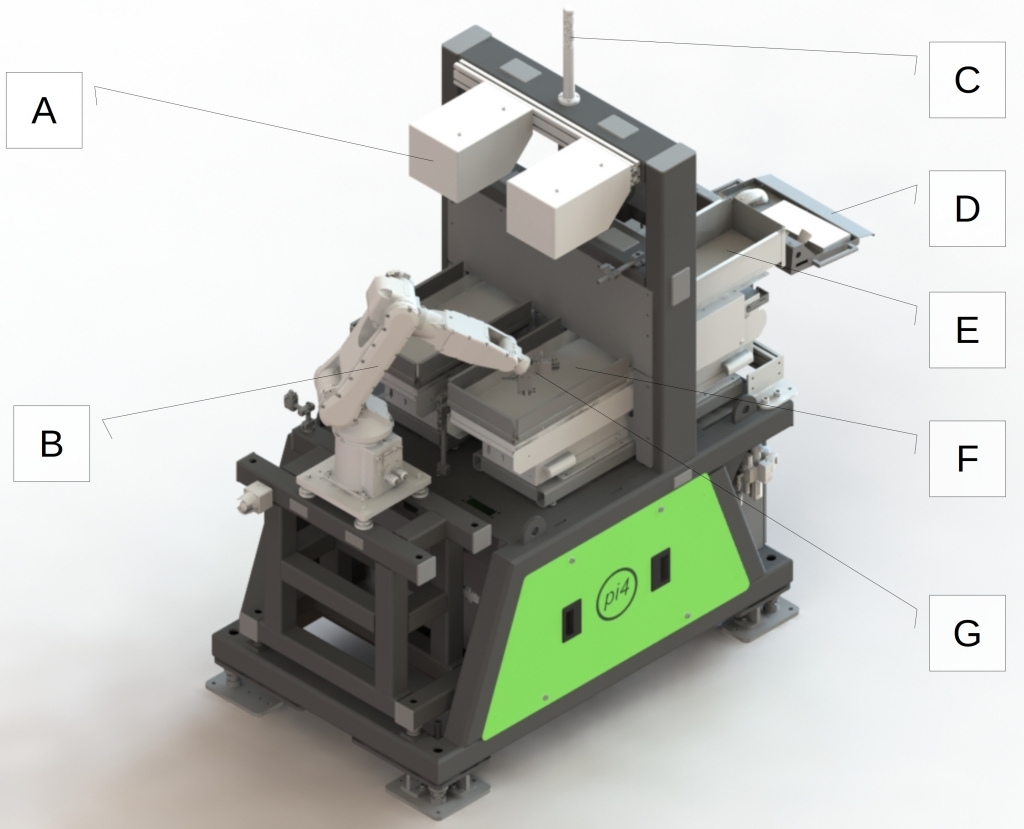

| A | camera unit |

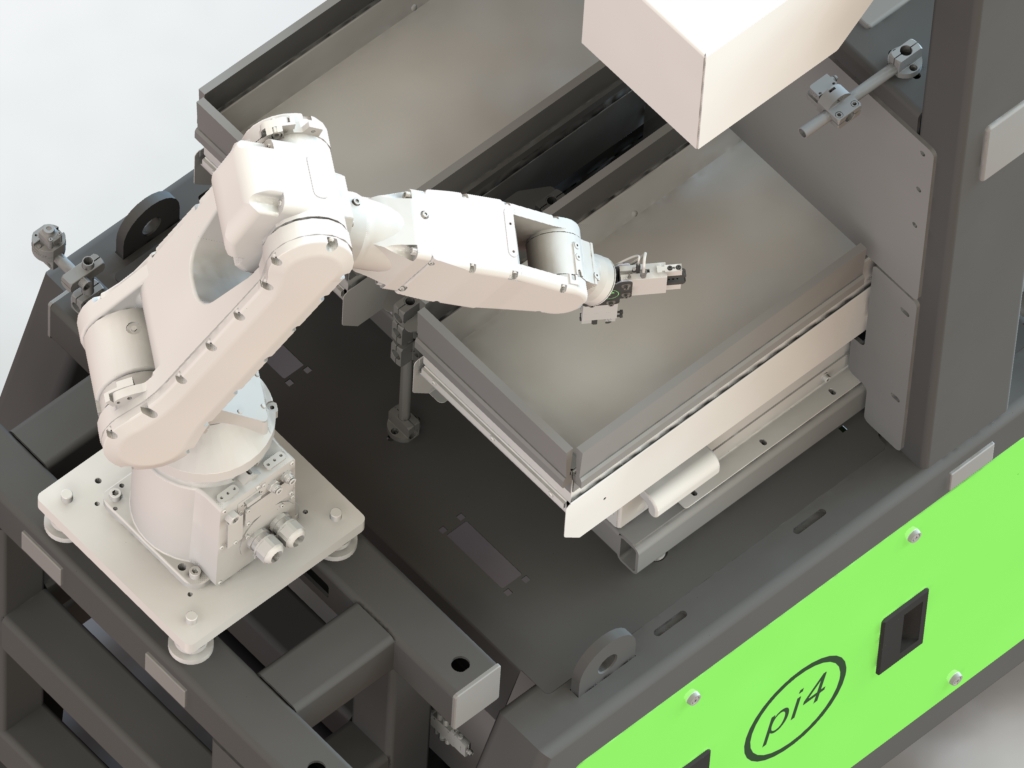

| B | robot |

| C | machine status light |

| D | user interface |

| E | storage container for parts |

| F | oscillation unit |

| G | robot gripper |

The Robofeeder-MC combines the capabilities of separating, sorting and quality inspection of parts in one machine. Your production parts are fed by a high-performance vibratory feeder into the correct position and precisely deposited on the delivery table by a robot.

The quality inspection of the parts according to your individual specifications can be performed “on the fly” within the work process.

Parts that do not meet your quality requirements are sorted out immediately. In the maintenance mode, the Robofeeder-MC is able to independently monitor its own gripping work. The user can check at freely selectable intervals with the integrated calibration camera whether deviations in the gripping accuracy have crept in.

This means that even the smallest parts can always be deposited with the highest precision. The Robofeeder-MC thus offers the highest possible performance for your handling and inspection process, seven days a week, 24 hours a day - and that with control and correction efforts reduced to an absolute minimum.

Even the setup of new production parts is possible without the need for extensive training in the machine software. The pi4_control control software can be operated intuitively.