Deep Tech Robotics Finalist

Berlin, July 2024 - pi4_robotics is a finalist at the Deep Tech Berlin Award Robotics 2024.

Our new Workerbot9 made it to the finals!

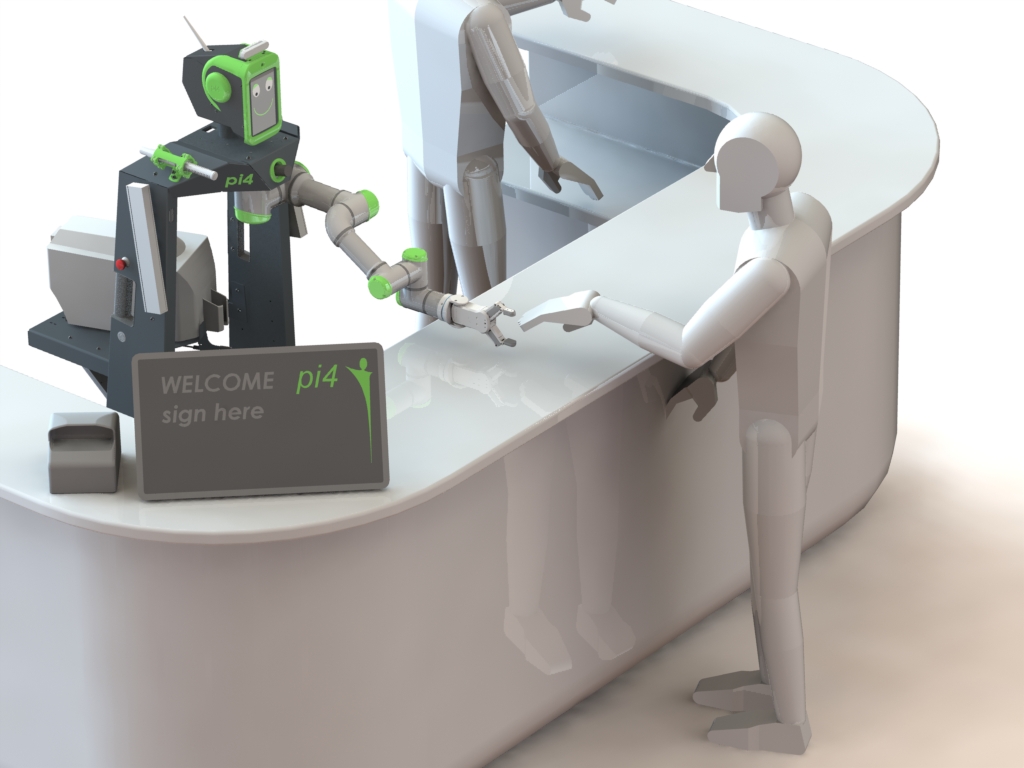

Opening of the kilofactory

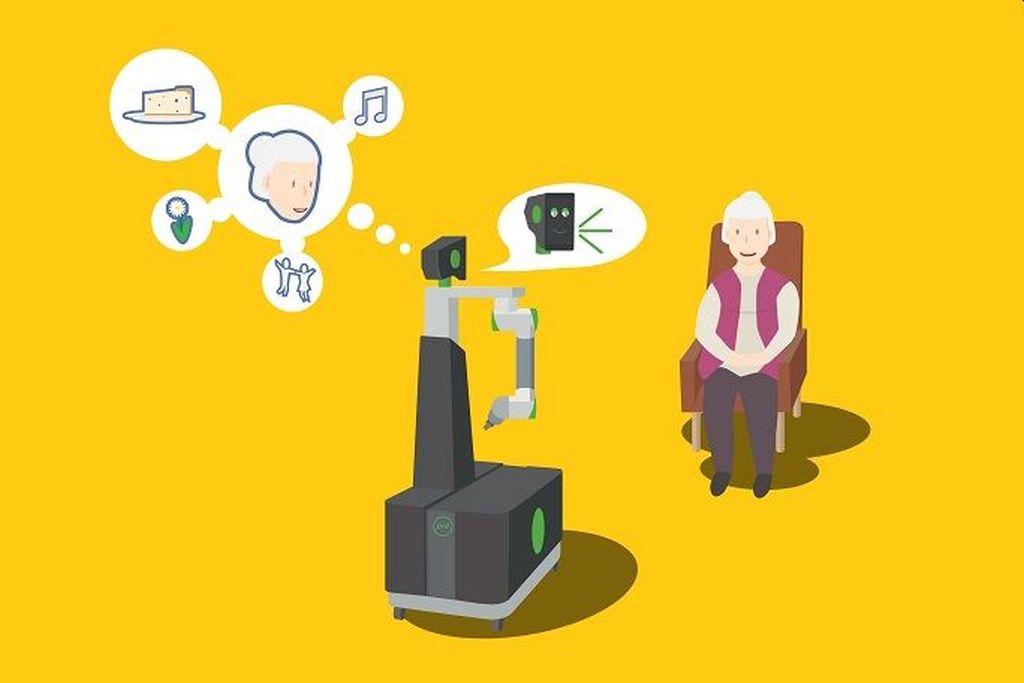

Berlin, July 2024 - Berlin Mayor Kai Wegner, Senator for Economic Affairs Franziska Giffey as well as other Senate members and the district mayor of Berlin Mitte Stefanie Remlinger took part in the opening of the new pi4_robotics “Kilofactory” for the production of service robots in Berlin Wedding. pi4_robotics will produce service robots for reception, nursing assistance, delivery services, security, telepresence and retail in quantities of initially 1200 robots per year. The company is taking an important step to make Germany the world market leader in service robotics. This is also an important component in alleviating the labor shortage in the service professions, especially in nursing. The nursing and support staff walk an average of 10-12 km per 8-hour shift. At an average speed of 4 km/h, they spend 3 hours of their shift walking. The Workerbot9 is a mobile nursing assistant robot for nursing facilities. The robot takes over delivery, information and accompanying services and thus reduces the walking distances of nursing and support staff. Thanks to a consistently modular concept and integrated AI for image processing, speech recognition and generation, the robot can also take on other tasks such as reception, security, advice and entertainment.

Programming as a service

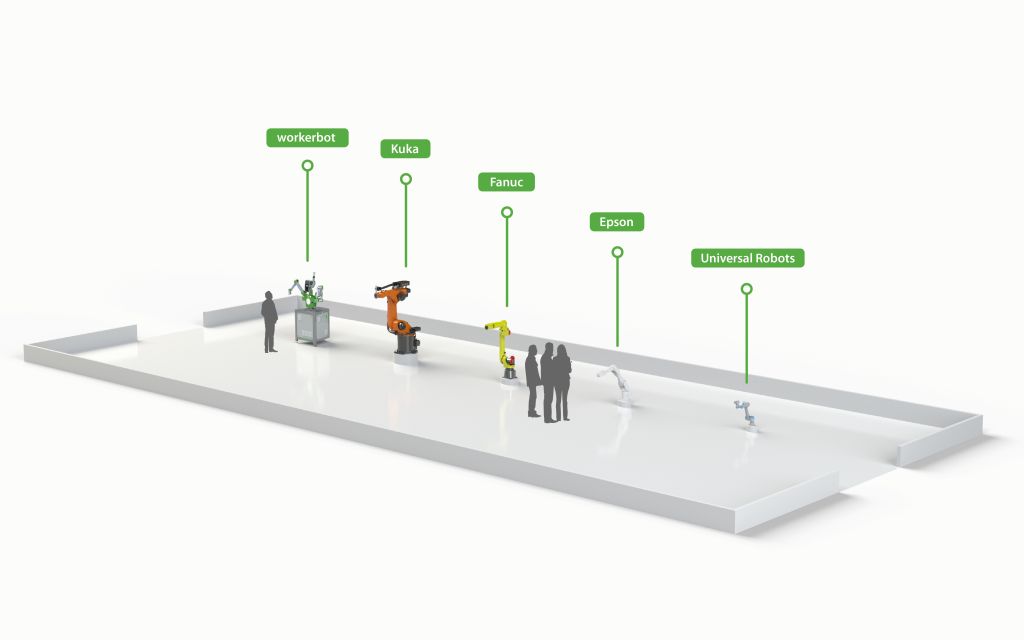

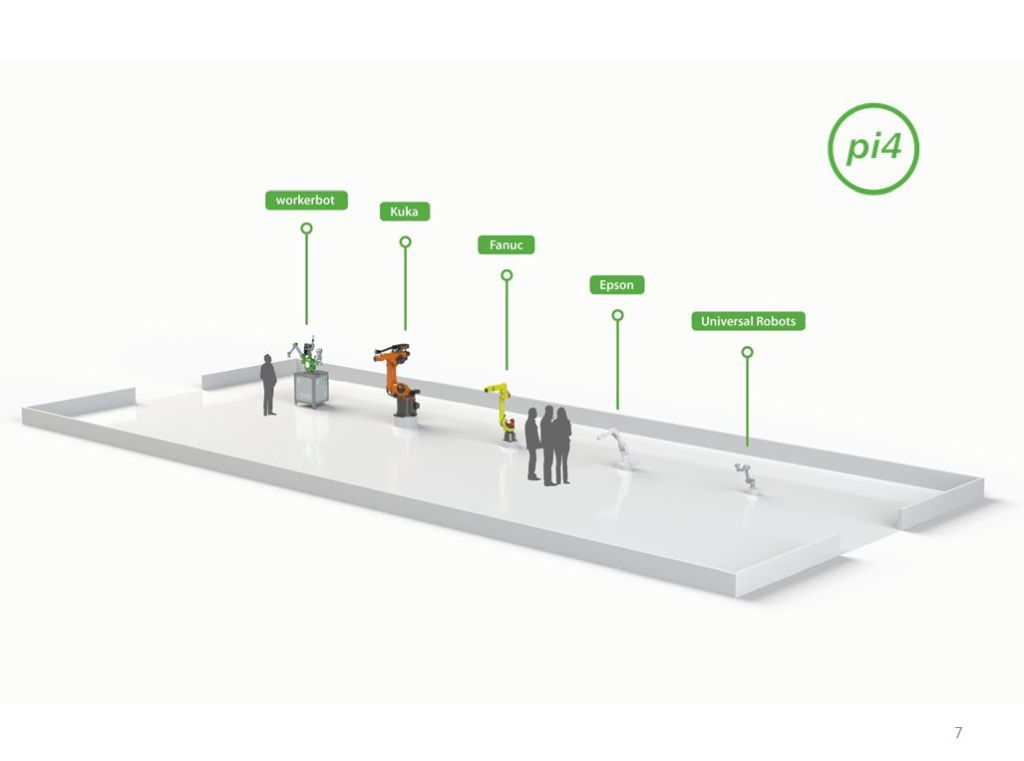

Berlin, June 2024 - Professional programming of industrial robots | pi4_robotics not only offers you complete automation solutions but also programming of industrial robots, as a service, from the manufacturer Epson, Fanuc, Jaka, Kuka, Nachi, UR and Workerbots from pi4 Requests: sales@pi4.de

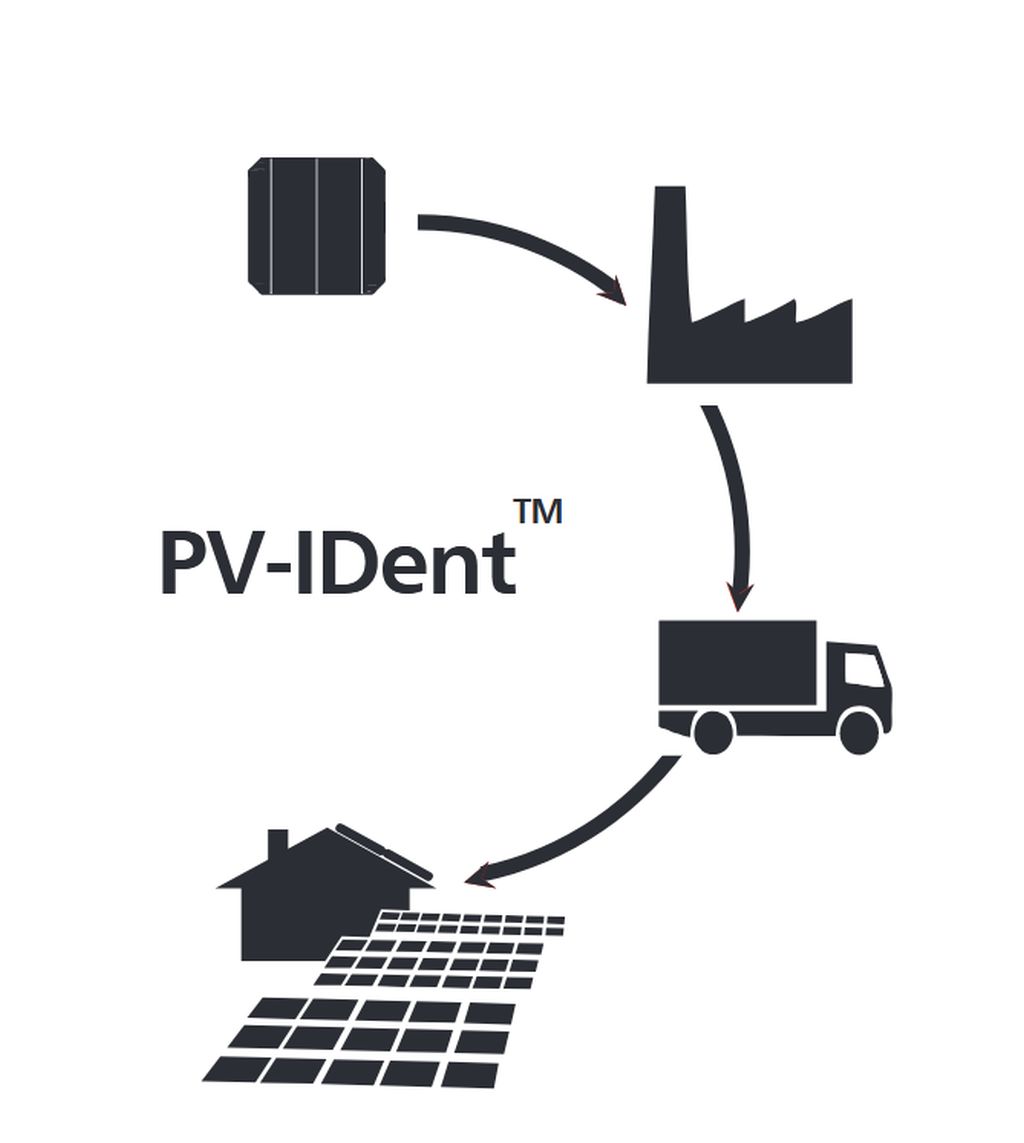

Expert lecture: PV-IDent

Berlin, June 2024 - Expert lecture: MatthiasKrinke at Intersolar München

“High Speed Cell and Module Quality Inspection based on Electroluminescence Imaging and AI Optimized Algorithms” PV-IDent.

Thursday, June 20, 2024 in Hall A2, Stand A2.409, 1 p.m Intersolar Europe.

pi4_robotics Technology leader in the field of fully automatic optical Quality control of Solar cells, strings and modules: Photovoltaic Industry.

LNDW with Workerbot9

Berlin, June 2024 - In 2021, 4.96 million people were in need of care within the meaning of the Care Insurance Act. According to the umbrella association of health insurance companies, the number of people in need of care increased to 361,000 last year. In addition, the number of nurses is decreasing. By 2049 there will be a shortage of more than 280,000 nurses. Care robots from pi4_robotics can help with this. radioeins reporter Julia Vismann meets one of them and is shown how self-determined living into old age could work at the Smart Living & Health Center e.V. at the Unfallklinik Berlin.

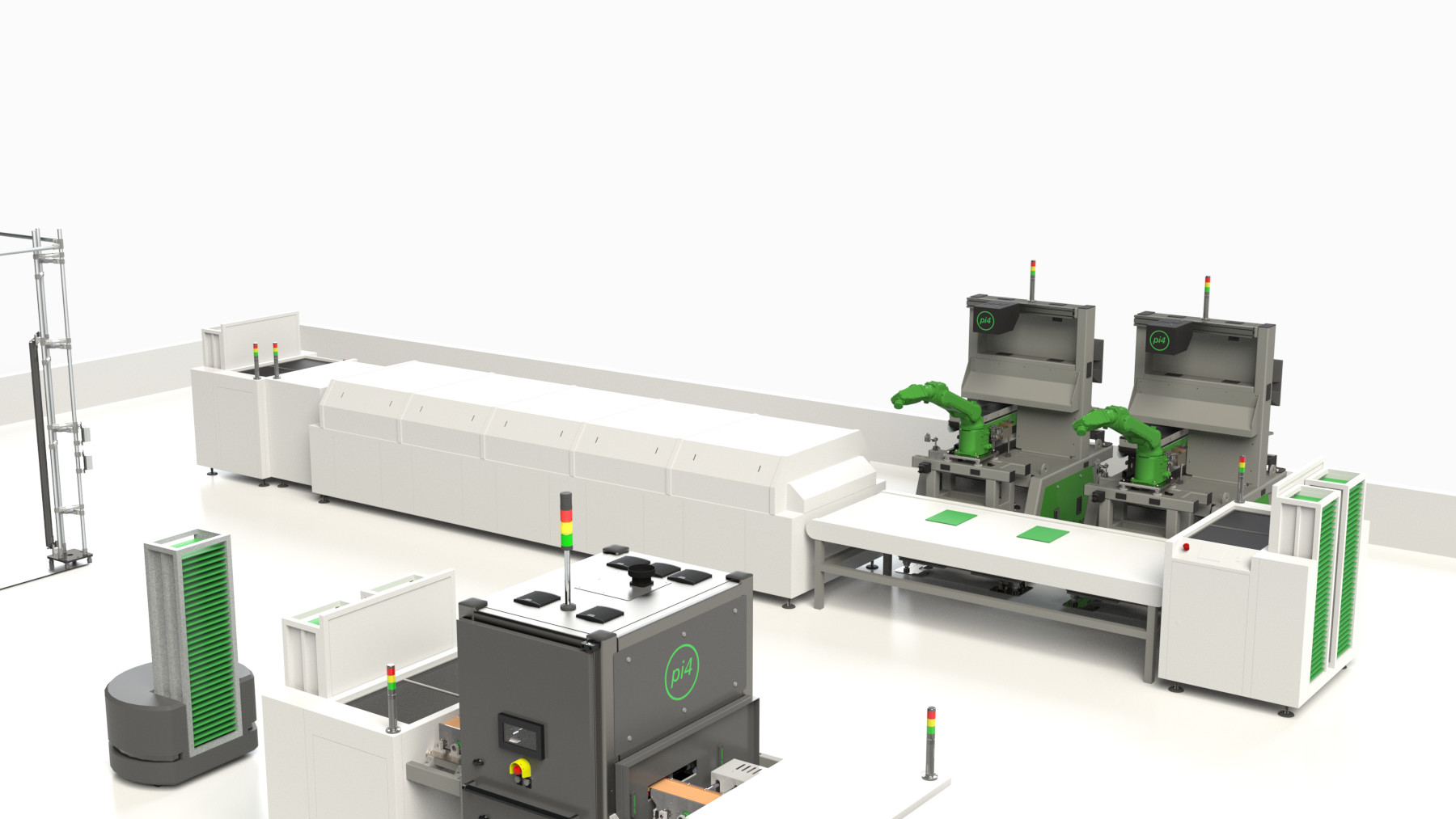

Intralogistics

Berlin, March 2024 - Intralogistics with the new mobile robots made in Germany from pi4_robotics. The new Workerbot17 series will not be exhibited at the Logimat in Stuttgart, but will perfectly support your production in all logistical transport tasks. We have a cloud-based fleet management especially for SMEs, which enables quick commissioning with minimal effort!

Berlin Creative Tech Summit 2023

Berlin, November 2023 - Our robot Workerbot9 Care-Home took over the drinks service for the Berlin Creative Tech Summit 2023

More information about the product: Workerbot9 Care-Home

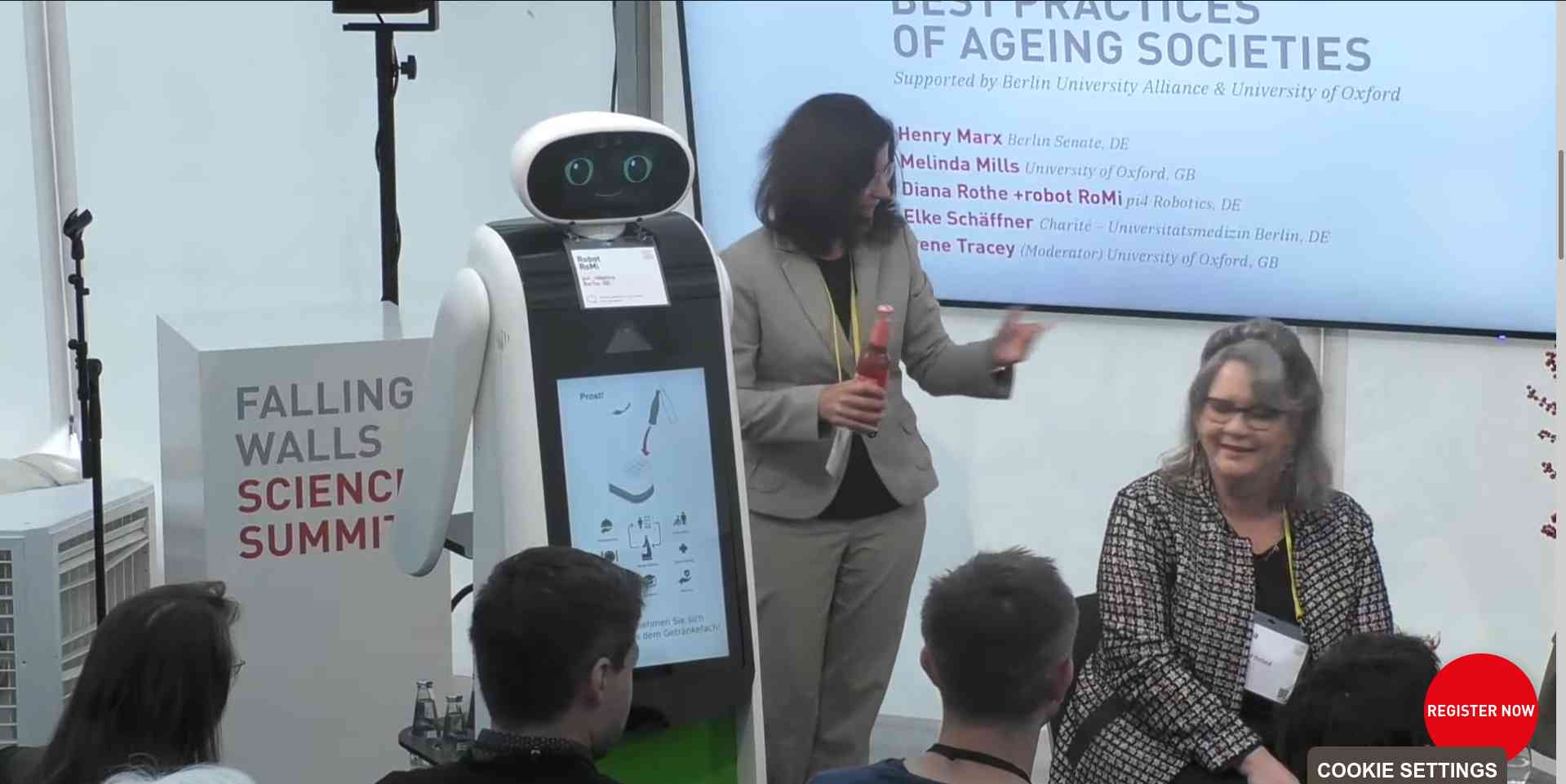

FALLING WALLS SCIENCE SUMMIT 2023

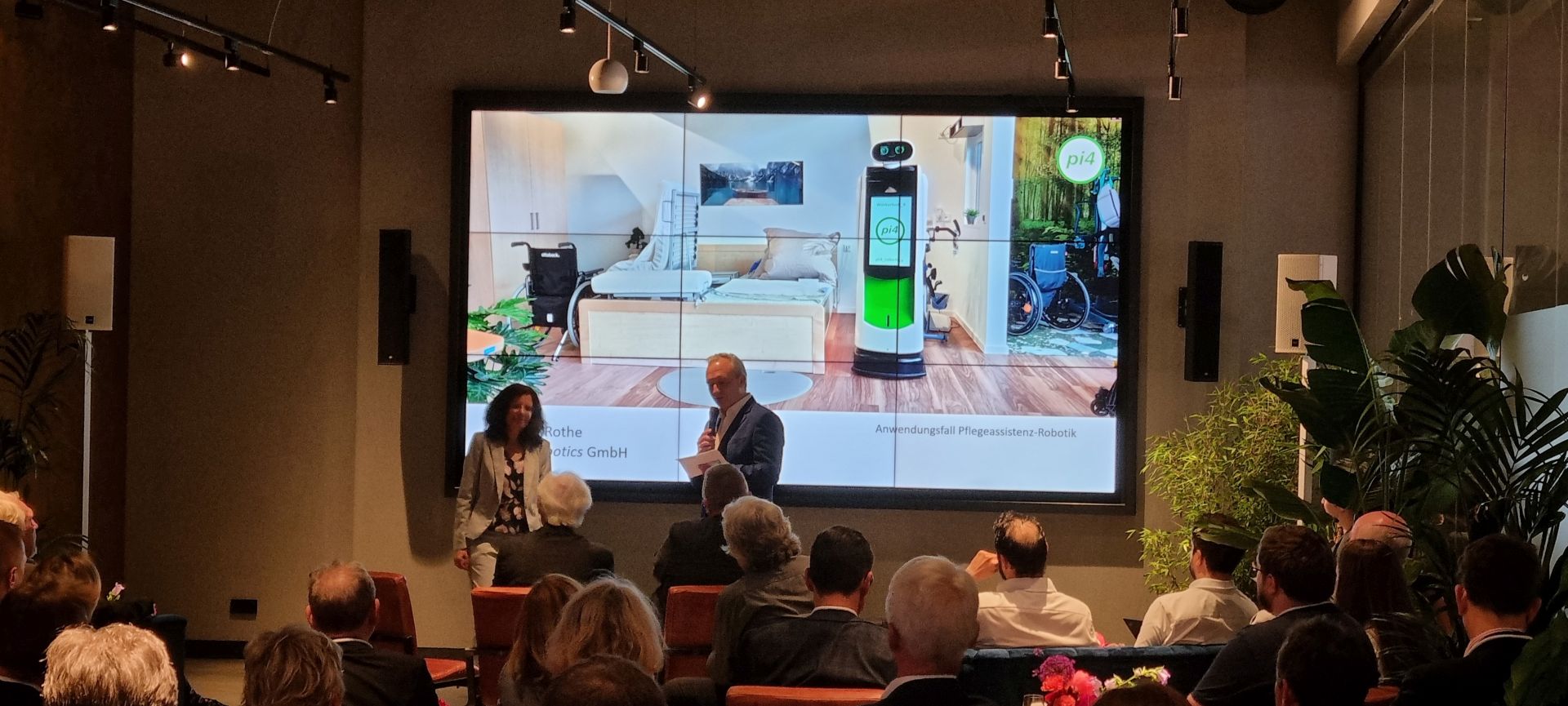

Berlin, November 2023 - Best practices of ageing societies Dr. Diana Rothe and the Workerbot9 Care-home robot RoMi from pi4_robotics on stage Challenges and best practices of ageing societies

More information about the product: Workerbot9 Care-Home

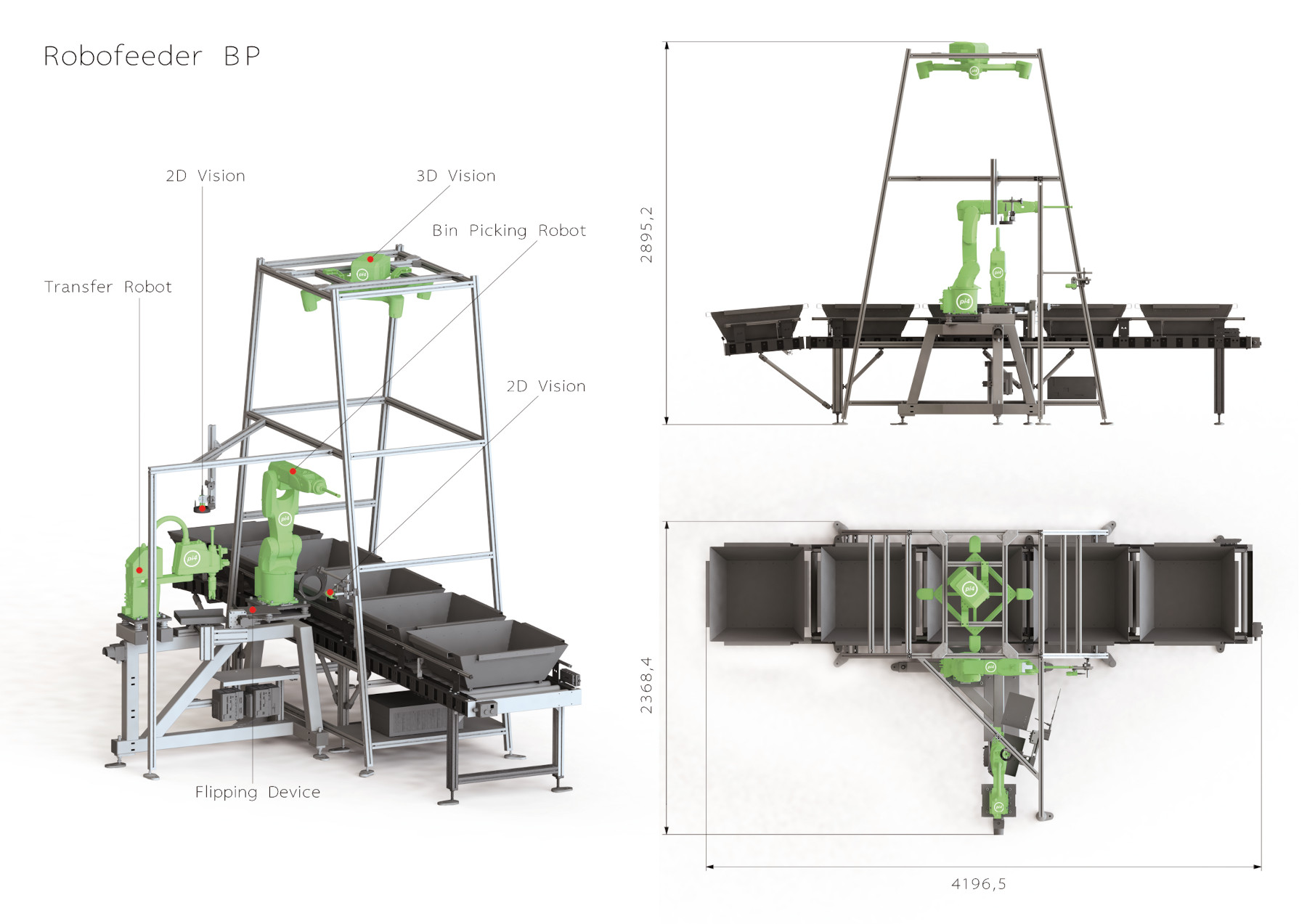

Bin Picking and Inspection

Berlin, November 2023 - The new Robofeeder-BP – Bin Picking and feeding.

The Robofeeder-BP combines the capabilities of separating, sorting and quality inspection of parts in one machine. Your production parts are fed by a high-performance bin picking feeder into the correct position and precisely deposited on the delivery table or the next machine by a robot. The quality inspection of the parts according to your individual specifications can be performed “on the fly” within the work process. Parts that do not meet your quality requirements are sorted out immediately.

More information about the products: Robofeeder-BP

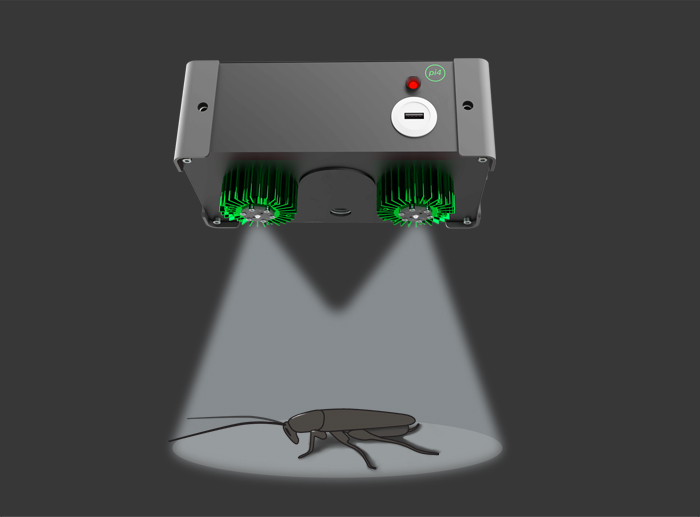

Bed bug plague in France: What is the situation in Germany?

Paris, October 2023 - Digital pest monitoring with automatic AI-based pest detection, developed and produced by pi4 Berlin, Germany. You should know who lives in your warehouse, hotel room, restaurant, shop, cinema or apartment!

More information about the product: Inseqtor

DPT2023 | Deutscher Pflegetag

Berlin, September 2023 - The Workerbot9 Care-home from pi4_robotics at the GermanPflegetag - the congress for care in Germany. The DPT2023 is the only national event organized directly by nursing representatives for nurses.

More information about the product: Workerbot9 Care-Home

Berlin ART WEEK | Security for Artworks with Robots – the Workerbot5 from pi4_robotics

Berlin, September 2023 - New security robots from pi4 in use

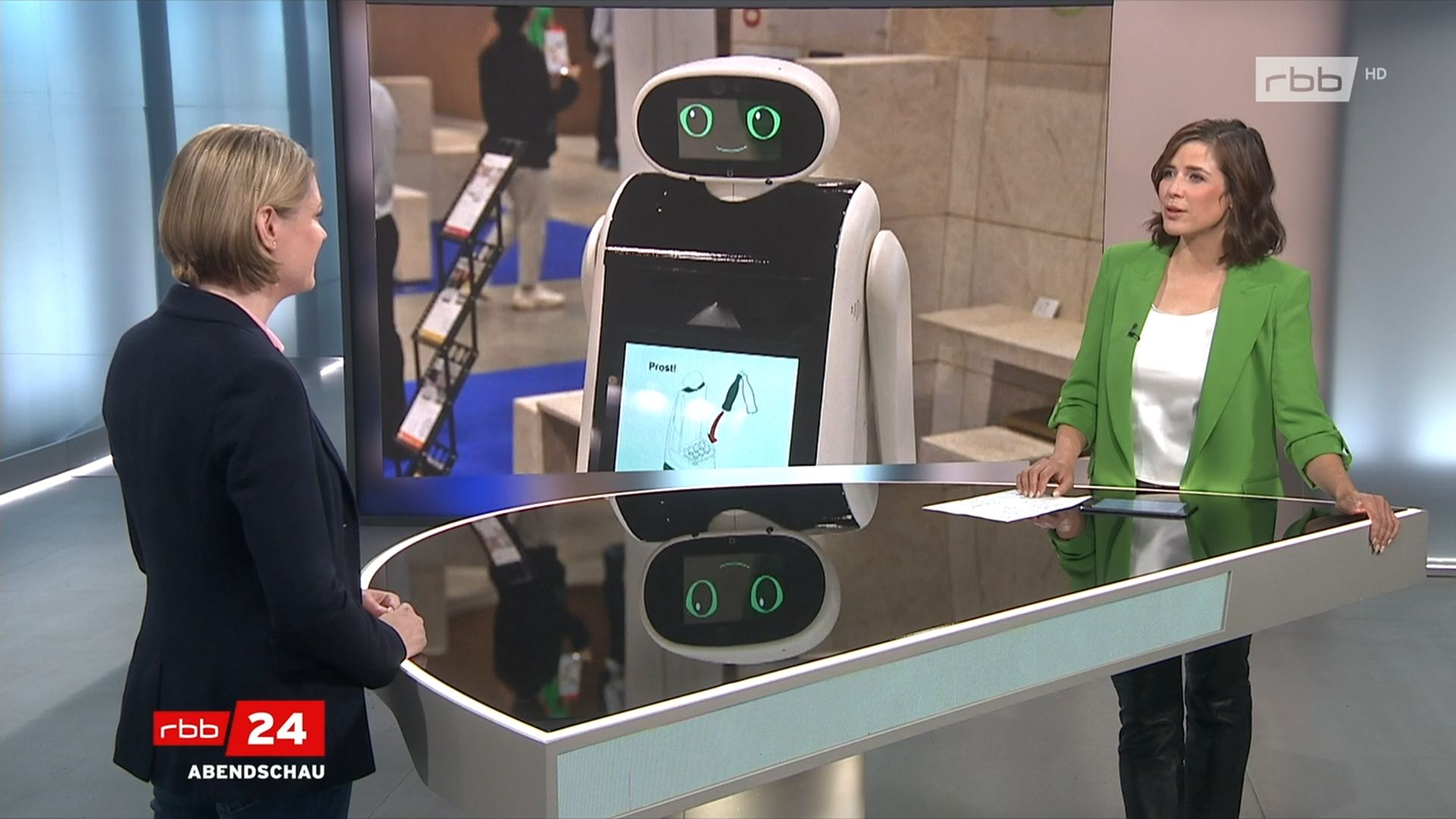

IFA2023 in Berlin | The new service robot Workerbot9 Care-Home

Berlin, September 2023 - Eva-Maria Lemke in pi4 colors with Workerbot9 Care-Home in the Abendschau studio.

More information about the products: Workerbot9 Care-Home

Unbeatable news at IFA2023 in Berlin

Berlin, September 2023 - Experience the latest generation of service robots from pi4.

Experience live at the trade fair: Workerbot9 - A robot with many facets - Areas of application (versions) like nursing assistant, concierge, room service, restaurant waiter, sales consultant, luggage carrier

More information about the products: Workerbot9 Care-Home

Robots built to help@Automatica

Munich, June 2023 - pi4_robotics presents the latest generation of service robots in the RobotCity A4.210 at the Automatica in Munich.

More information about the products:

TDI23 | How artificial intelligence and robotics are accelerating the transition to the future

Berlin, June 2023 - Dr. Diana Rothe presents the latest generation of service robots.

More information about the products: Workerbot9 Care-Home

Intersolar 23 | Quality inspection of cells and modules from pi4_robotics

Munich, June 2023 - Dipl.-Ing.(Univ.) Matthias Krinke presents the latest generation of ai based machine vision solutions.

More information about the products: PV-IDent

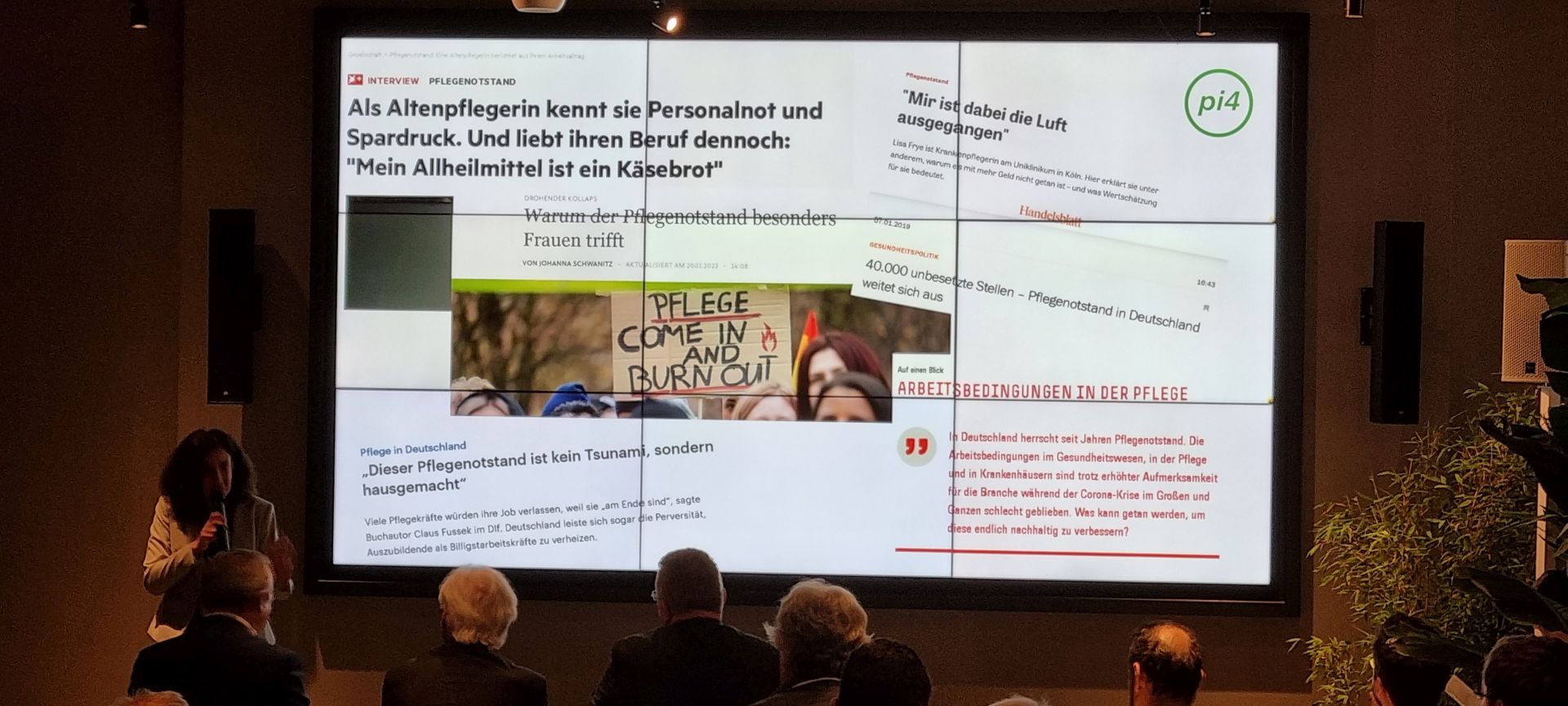

How robot RoMi should alleviate the nursing shortage

Berlin, May 2023 - In 2030, there will be an estimated 350,000 nursing staff shortage in Germany. People are getting older and there are not enough young people to care for them because the job is tough. That is why robots are being developed at pi4 in Berlin, which are intended to relieve the nursing staff. By Franziska Ritter rbb24 INFORADIO

More information about the product: How robot RoMi should alleviate the nursing shortage

Opening of the retail Garage at The Playce Potsdamer Platz Berlin

Berlin, April 2023 - The Retail Garage is the meeting point in Berlin for professional and practical exchange on future-oriented retail technologies. The showroom imparts knowledge, enables dialogue and shows solutions for digital trade. It explains innovations and illustrates the attractiveness of one of Germany’s largest employers. The retail of the future can be experienced, among other things, through changing exhibits on 300m² and the showroom can also be used as a rentable event space.The Retail Garage is a joint project by Handelsverband Deutschland e.V. (HDE), EHI Retail Institute and Mittelstand-Digital Zentrum Handel.

In the Retail Garage you can now experience one of our Workerbotkiosks in person 24/7. https://www.potsdamerplatz.de/de/stores-food-drinks/retail-garage-workerbot

More information about the product: Workerbotkiosk

The Workerbot9 Care-home is well received by #caregivers !

Berlin, April 2023 - Great interest in robotics to relieve caregivers at the Altenpflegemesse Nuremberg. Together with its partner HIDREX, pi4_robotics presents an extensive portfolio of robots to support caregivers.

More information about the product: Workerbot9 Care-home

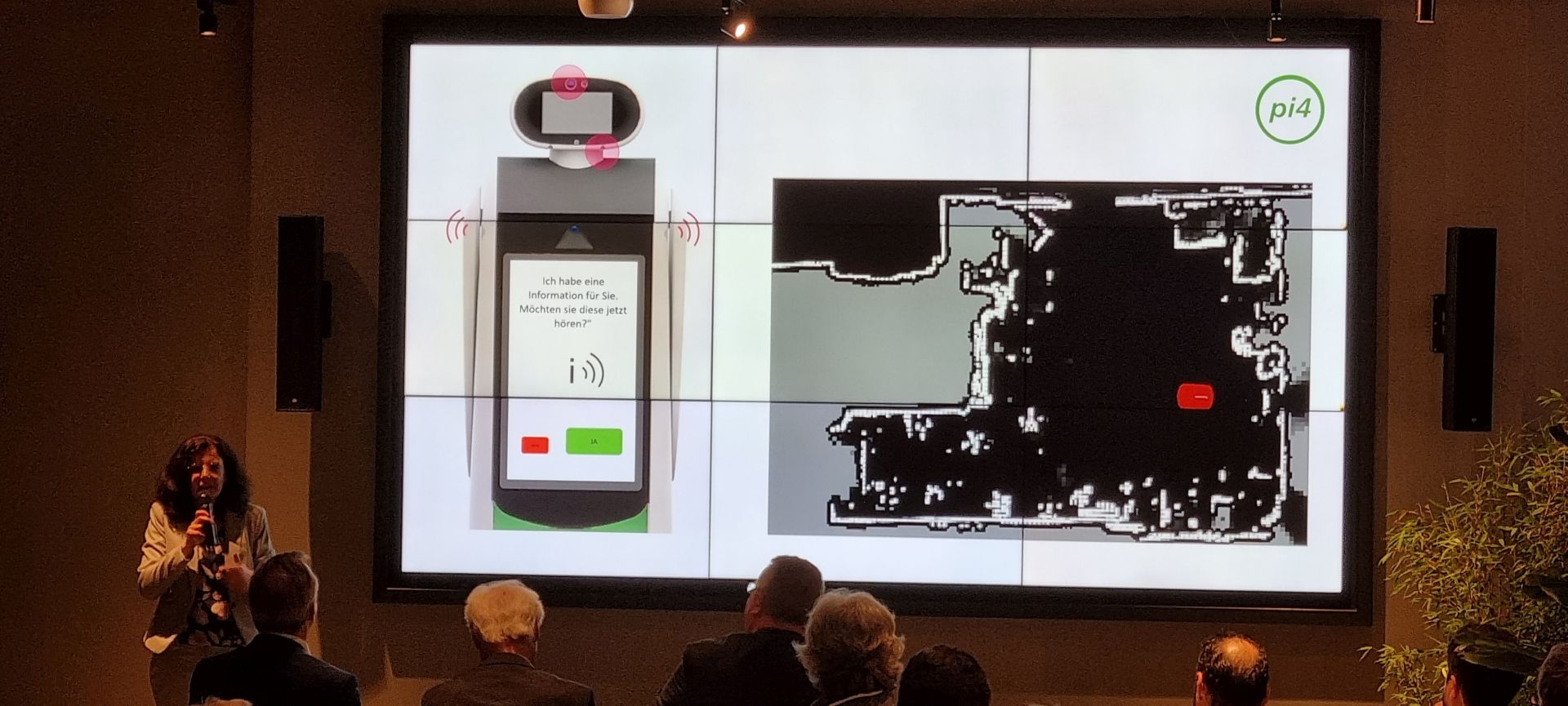

Workerbot9 Care-home - Nursing staff should care - a new robot does the rest

Berlin, April 2023 - Many nurses walk more than 12 kilometers a day. A route like from the Brandenburg Gate to Marzahn, for example to the accident hospital in Berlin. In its immediate vicinity, a robot was presented today that could soon relieve nursing staff of most of their journeys. So that they can finally concentrate on their qualified tasks - overdue in times of the nursing shortage. The Johanniter want to use the Workerbot9 Care-home in practice soon. “Hello, Mrs. Schultz, there you are!” The new helper in the nursing team has already noted the face and the name of his new patient. On the way to her bed, he maneuvers around a visitor with agility. He brings Mrs. Schultz her lunch and her favorite drink and reminds her to take her medication. Then the robot glides out of the room and drives to the next patient. The small scene may soon be part of everyday life in hospitals and nursing homes. “We are proud to present the first and only care assistance robot in the world today,” said Matthias Krinke, Managing Director of pi4_robotics GmbH. The manufacturer of the Workerbot9 Care-home has found a suitable location for the press conference: The “Smart Living & Health Center” in the house of the future at the Unfallkrankenhaus Berlin. Since 2021, the house has been providing information on how technology can help lead a self-determined life despite health restrictions. Today journalists got to know the Workerbot9 Care-home. Professionals from the care sector are already convinced of its potential - after all, it was developed in consultation with them. “We see many good reasons to use robots like this,” said Luis Rulle from Johanniter Berlin at the press conference. The Workerbot9 Care-home takes on exactly those strenuous routine tasks that have often made the job of caregivers difficult. It tows up to 150 kg. His tray manages 10 kg - for example portions of food and other objects. He also likes to carry 12 drink bottles. He himself is extremely undemanding: With only 3 hours of “sleep” (charging time) he manages a 12- to 18-hour shift. Always on the move between patients, the kitchen, storage rooms or wherever else it is needed. Thanks to its cameras, laser sensors and safety zones, it doesn’t bump into anyone, but in an open corridor it is faster than most pedestrians: up to 5.4 km/h. “Let’s assume that nursing staff actually spend around three hours of their shift running,” calculates Matthias Krinke. “According to the German Economic Institute, there could be a shortage of around 307,000 nursing staff in Germany by 2035. If robots only take over two of the three hours of walking per shift, then the requirement drops by 76,500.” The Federal Ministry of Education and Research has also recognized that robots could be decisive in the fight against the care shortage: It funded the development of the Workerbot9 Care-home in the “RoMi” project (“Robot support for routine tasks to strengthen cooperation in care facilities”). In Germany, a nurse currently looks after 13 people - much more than in the Netherlands or the USA. Demographic change is exacerbating the nursing shortage. Therefore, it is imperative that human caregivers can focus better on skilled tasks – and run less. More information about the product: Workerbot9 Care-home

EvoFrame - Ready to change: New project explores models for the evolution of companies

Berlin, Januar 2023 - Every organization is under pressure to change – and the pace is increasing always on. “Change competence” now plays a key role for the success of companies. The tasks that they have to master for this lie in many areas: It’s about work psychology and human-machine interaction, it needs social and technical solutions. Now studying a unique project models from research and practice for how change can succeed. Sponsored it is administered by the Federal Ministry of Education and Research.

Innovations for the production, services and work of tomorrow

Workerbot3 DJ - Fully automated DJ robot

Berlin, January 2023 - The greatest DJ in the world! DJ Rob comes to you — an eye-catching centerpiece for your hospitality or entertainment venue. Spinning records, playing music by request or preprogrammed selection—the DJ robot is a unique performer with high audience engagement. He moves to the beats and likes to interact with his audience. His lights create a full range of atmospheres. DJ Rob’s mission: to put a smile on people’s faces. More information about the product: Workerbot3 DJ

pi4 is there for you 365/366-24, including public holidays!

More information about the service: Service by pi4

We wish everyone in the world ! Liberty Equality Fraternity >Peace

Automation for electronics production, from your specialist pi4

Berlin, November 2022 - We help EMS service providers in Germany to produce competitively! Robots separate, check and assemble THT components. More information about the product: THT Placer

Kitchen Help; 5347 vacancies at the employment agency

Berlin, October 2022 - pi4 cannot help you with every task in the kitchen. But the Workerbot3 Kitchenhelper can safely and reliably load the food containers in commercial kitchens with food trays. He is also happy to carry out quality control and check that the trays are completely and correctly loaded for each individual patient or guest. So just keep waiting for natural persons for your company or decide for short-term available electronic persons from pi4. More information about the product: Food Industry

Automation for electronics production, from your specialist pi4

Berlin, September 2022 - We help EMS service providers in Germany to produce competitively! Automatic testing of electronic assemblies, now optional with integrated lasermarker.

More information about the product: Workerbot8

Robot Gisela Workerbot suspected of murder

Berlin, August 2022 - WDR television | Crime scene: Actor Gisela from pi4_robotics plays Robista in a pi4 workerbotkiosk and is suspected of murder. Also see Yolandi Workerbot, spokesperson for the robot temp agency Robozän in a supporting role. To the show: “Tiere der Grossstadt”

More information about the product: Workerbotkiosk

pi4_robotics liefert unbegrenzt qualifizierte und hochmotivierte Arbeitskräfte

Berlin, Juli 2022 - Der Workerbot3 für Ihre Produktion. More information about the product: Workerbot3

Laboratory robots from pi4 have been saving lives for 14 years:

Berlin, June 2022 - Robot-assisted cancer and ALS (Amyotrophic Lateral Sclerosis) diagnosis with CytoFa, a compact, configurable and cost-effective robotic laboratory with high-performance fluorescence microscope from Zeiss. More information about the product: CytoFa

The high speed robofeeder from pi4

Berlin, Mai 2022 - Bulk material separation, infeed and quality control in 0.8s

More information about the product: Robofeeder-HA

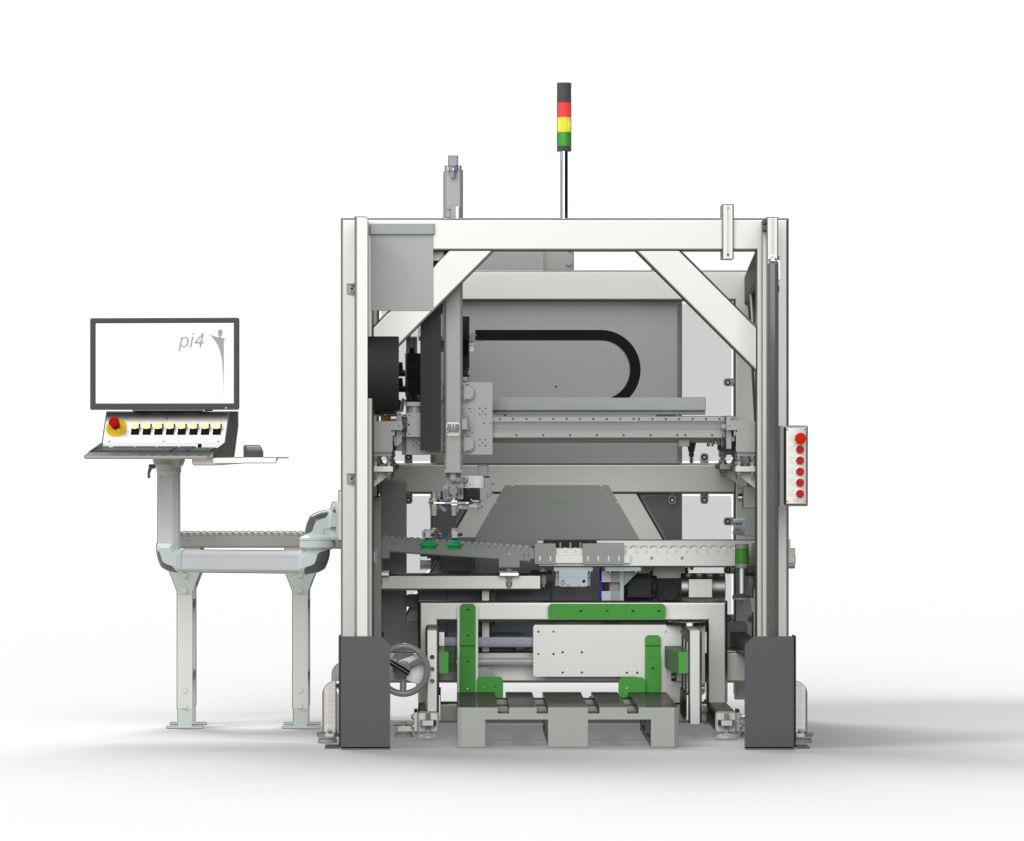

Fully automatic quality control of solar modules

Berlin, April 2022 - German quality at a Chinese price - electroluminescence solar module tester Efficiency XL from pi4 | EL inspection with up to 185.4 Mpixel, 122 μm/pixel resolution - Cycle time from 18s with parallel insertion and removal - Module sizes up to 2300mm x 1200mm, modules pre-laminated, laminated with or without frame - Conveying height 920 - 1050mm, up to 400mm/s - Automatic contacting on plugs or J-Boxes - Cell sizes from M3 to M12 - Full and half cells - mono- or multi-crystalline cells and optionally with integrated distance measurement. More information about the product: Efficiency XL

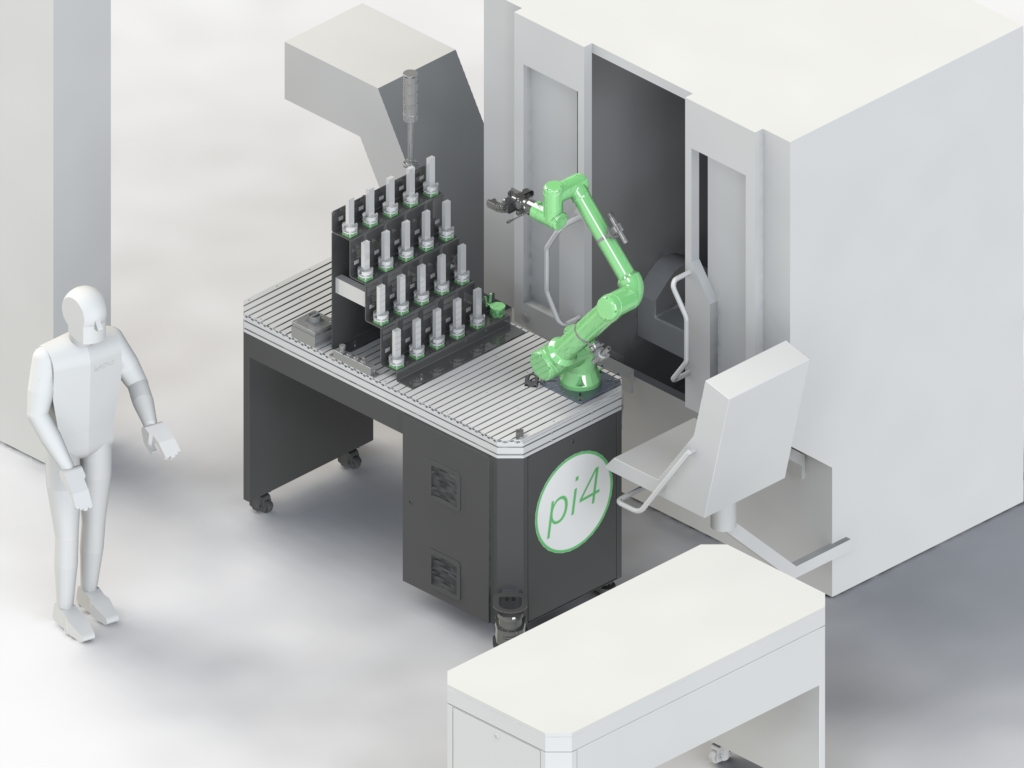

Your new 24/7 employee at the CNC machining center:

Berlin, March 2022 - Are you looking for a reliable, tireless and precise employee for loading and unloading your CNC machining center? Then the Workerbot7 is the perfect employee for your company. It can open the manual doors of your machine with the gripping hand, cleans the interior with its integrated drain function in the gripper, can relax, remove and set down your workpieces and insert and clamp new workpieces. You don’t need any special knowledge, the robot calibrates itself to the machining center all by itself after starting. More information about the product:Workerbot7

PickClothBot, a robot for sorting dirty laundry

Berlin, February 2022 - The PickClothBot from pi4_robotics is able to automatically sort dirty laundry. The system is mainly used in laundries, hospitals or care facilities. It relieves employees of monotonous activities and makes a major contribution to occupational safety, since employees no longer come into contact with contaminated laundry when sorting it. The soiled laundry is brought to the robot on a feeder. The robot has a 3D camera and can recognize and pick up individual items of laundry using AI-based image processing algorithms. A RFID scanner is able to read information about the individual items of laundry, such as colour, washing temperature or other data. The robot then sorts the laundry according to its properties into different boxes on discharge belts. Of course, the same system constellation can also be used for sorting the clean laundry back by customer or person. We would like to thank the BMWK Federal Ministry of Economics and Climate Protection for the funding! More information about the product: PickClothBot

Inspectoid for fuelcell bipolar plates

Berlin, January 2022 - A fully automatic 2D- and 3D optical inspection system for bipolarplates. pi4 offers since fourteen years inspection systems that can be integrated seamlessly into production processes. Thus individual cells can be inspected with maximum precision, so that defective cells can be rejected immediately. More information about the product: Inspectoid for fuel cell bipolar plates

Trust in cash

Berlin, December 7, 2021 - When packing coins, German mints have relied for more than 12 years on the palletizing robot from pi4_robotics. This well-proven R3000 robot is probably the most trusted “employee” you can get for this particularly sensitive industry.

But it can do much more. Time for promotion: As a series product from pi4_robotics, the R3000 has earned the trust of coin producers over more than 12 years of its use in coin packing. But as the industry is discrete and secretive, that is the reason why pi4_robotics is only now putting its palletizing robot in the spotlight-after all, it can pack almost anything in a similar weight class as coin packs.

Flexibility is the core competence of the R3000: the end user can quickly, easily and directly adjust almost everything about it. Which pallet size should be packed? Or are crates preferred to pallets? How many layers should be packed? What should the layer and stacking patterns look like? Different layer patterns within a stack are also possible. New palletizing schemes can be set up immediately without a programmer. And all this can be applied directly on the equipment, with software that works as intuitively as it does reliably. Customers confirm this: “We use several palletizing robots from pi4_robotics”, says the Managing Director of the Bavarian Main Mint (Bayerischen Hauptmünzamt), Günther Waadt, “and have namely done so for many years. We are particularly impressed by the reliability, ease of operation and compact design”. Compactness is the second great strength of the R3000: It fits with its small footprint into normal rooms with its height and width of only 2.10 m, and the depth is also tight at 2.70 m. Added to this is speed: with its suction pad gripper, the R3000 moves products into place at up to 1.5 meters per second, with short cycle times from as fast as 5 seconds. It works without requiring a compressed air supply. Its roller conveyor docks onto existing conveyor systems.

“So the R3000 also plays a first-class role in part feeding”,says pi4_robotics Managing Director Matthias Krinke. “It fits smoothly into production. Integration of the R3000 into the coin roll packaging systems we supplied has worked excellently”, says Andreas Radmer, managing director at coin rolling machine producer NGZ Geldzählmaschinengesellschaft GmbH & Co. KG. in Dahlewitz, Germany. “R3000 impresses our mutual customers with its reliability and low maintenance costs and works perfectly with our components. Above all, it’s so robust that it doesn’t immediately get loading restrictions or error messages when things occasionally go wrong, and that’s just what happens in factories sometimes”. Should problems do occur, there is online remote maintenance available directly from the producer.

If the R3000 operates around the clock, it will have been amortized within a year. This equipment, on which German mints have relied for more than a decade, is thus also suitable for many other industries. Still, it’s especially useful for anyone who handles sensitive products. “This employee would never steal, and he doesn’t talk after work about how many expensive products he packed today”, says Matthias Krinke. “With a human being, you would say: hardworking, trustworthy and discrete”.

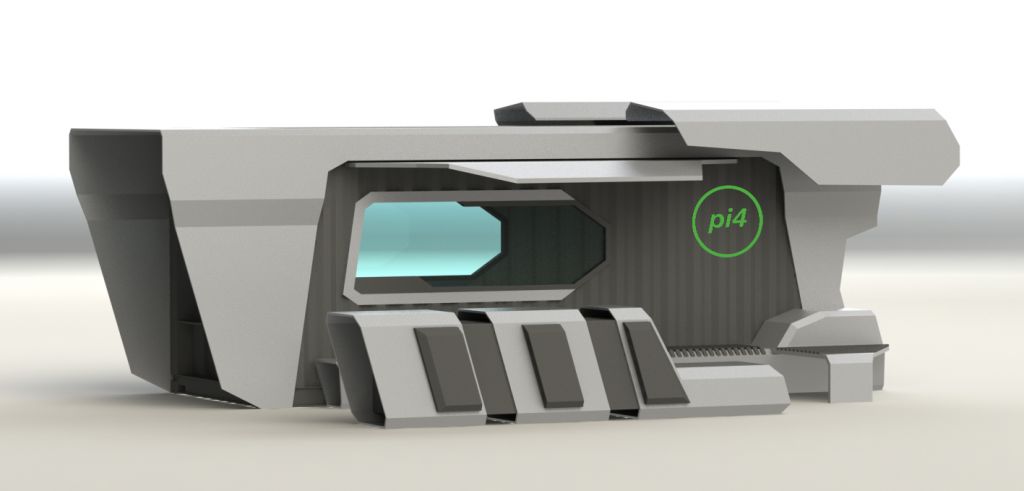

Check-in under 3 minutes!

The concierge robot Workerbot4 from pi4 now also checks compliance with the 3G rules and of course politely, reliably, quickly, hygienically and GDPR compliant. Buy from pi4_robotics GmbH Rent from Robocene / Robocene

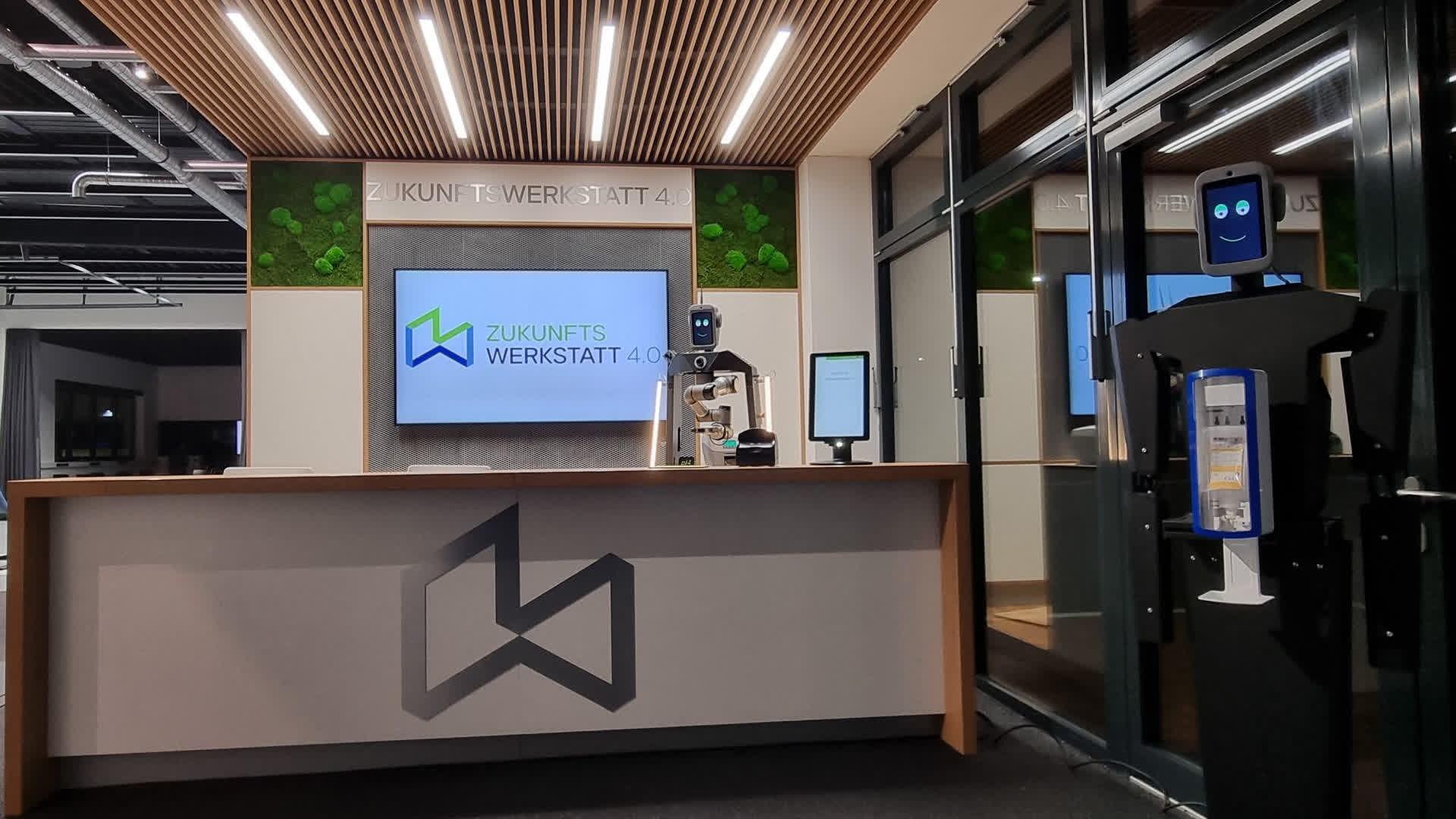

The future workshop 4.0 is open!

Stuttgart, November 2021 - The innovation lab for car dealerships and garages in Esslingen near Stuttgart is an innovation showcase, training center and test laboratory for new technologies, processes and business models. At the opening, pi4_robotics, as an innovation partner, showed the latest generation of the Workerbot4 Concierge , for fully automated check-in, in the car dealership. In the presence of Matthias Krinke and representatives of the other 94 partner companies and institutions, the State Minister for Economic Affairs BadenWürttemberg The Länd, Dr. Nicole Hoffmeister-Kraut handed over the Zukunftswerkstatt 4.0 to the operating company.

Circular Economy: Innovative solutions for sustainable production processes.

The Berlin-based robotics company pi4_robotics GmbH was honored with an innovation award for the fourth time in February 2021, the 13th award so far received by the company.

The magazine Capital awarded the company pi4_robotics for being one of the most innovative companies in Germany in the category “mechanical engineering / up to 250 employees”. According to Capital, it is precisely in difficult times that German companies show how a crisis can be a driving force for innovation. For pi4_robotics, however, there is usually no need for a crisis: “Innovation has been our DNA since the company was founded. But, of course, this further award is motivation and, above all, an additional incentive for us to stand by our customers with support and best possible advise, also in difficult times”, explains Matthias Krinke, CEO and founder of the robotics company, which celebrates its 27th birthday this year.

A building block for sustainable and economical production in Europe

Aside from economic aspects, ecological production conditions also play an increasingly important role. And Europe is also increasingly becoming the focus of many manufacturing industries as a production location. “The decisive factor for us is the holistic approach that we offer our customers. In addition to expert advice, we are particularly committed to helping our customers to become pioneers in the circular economy, from product development, through production, to final inspection”, says Krinke. This specifically involves sustainable product design, in which automatic production is already taken into account during product development and which allows fully automatic disassembly and recycling at the end of the product’s life. This not only saves enormous costs and resources, but awareness of responsibility paired with environmentally friendly production methods also ensures good quality standards and service, along with credibility. A bonus of trust that pays off for more and more companies.

Speed is an important factor in innovation

It takes many steps from the initial idea to a marketable product. A circumstance that often takes up too much time in a fast-paced world. “As a founding member of the Werner-von-Siemens-Centre for Industry and Science e.V., we have therefore set ourselves a goal of increasing speed and innovation performance through close cooperation between research, teaching and industry on our campus in Siemensstadt 2.0”, explains Krinke. With three research projects already underway, pi4_robotics GmbH is actively driving the change in production technology and planning mobility and energy transition projects. The company is very open to new cooperation partners: “We would like to invite other companies to break new ground with us and to research and work together in high-performance teams of the WvSC e.V. at the Berlin location”, Krinke concludes.

Related links:

Flexible feeding of bulk goods

Berlin, February 2021 - Flexible feeding of bulk goods. Fast, reliable, gentle and with optical quality control of your components. The Robofeeder. from pi4 separates and controls your components with cycle times of up to 1.5s per component. More than 26 years of experience have gone into the proven and robust series hardware, which is now being delivered with the latest AI-based image processing from pi4. The new software makes it possible to learn new products quickly and with little effort.

R&D project RoMi: Robotics4Care

Berlin, February 20201 - R&D project RoMi: Robotics4Care.

Research and development project for the use of #servicerobots in care. The combination of the confidence-building design of the robot and technological improvements promotes the use and acceptance of supporting robots in care practice. This will reduce the workload for the care staff and increase the quality of care. See here.

Workerbot6p

Berlin, February 2021 - The autonomous Robot Workerbot6p from pi4 is a mobile HRC-capable Cobot and has AI based 3D image processing. In one system, it combines the strengths of the sensitive lightweight robot UR5e from Universalrobots and a mobile, autonomous platform with SLAM navigation. The WB6P is location-independent and highly flexible - the ideal prerequisite for the requirements of Industrie40.

Workerbot7

Berlin, January 20201 - Machining centers fully automatic loading and unloading, with the Workerbot7 from pi4: Do you have an older machine with manual doors? No problem, the robot can open and close the doors. The Workerbot7 also takes over the clamping, releasing and blowing off of the workpieces. Do you want to machine parts with manual loading during the day? No problem, you simply push the Workerbot7 aside. Who calibrates the position of the robot in relation to the processing machine? The robot does it by itself, you don’t need an employee with robot experience.

You find this solution interesting, but want to test the robot for 4 weeks first? You can rent the Workerbot7 from robocene.

24/7 Service by pi4

Berlin, January 2021 - 24/7 Service by pi4: With our global network and by using the latest means of #servicerobotics and communication, we can offer our customers the outstanding service of a global market leader. See Service.

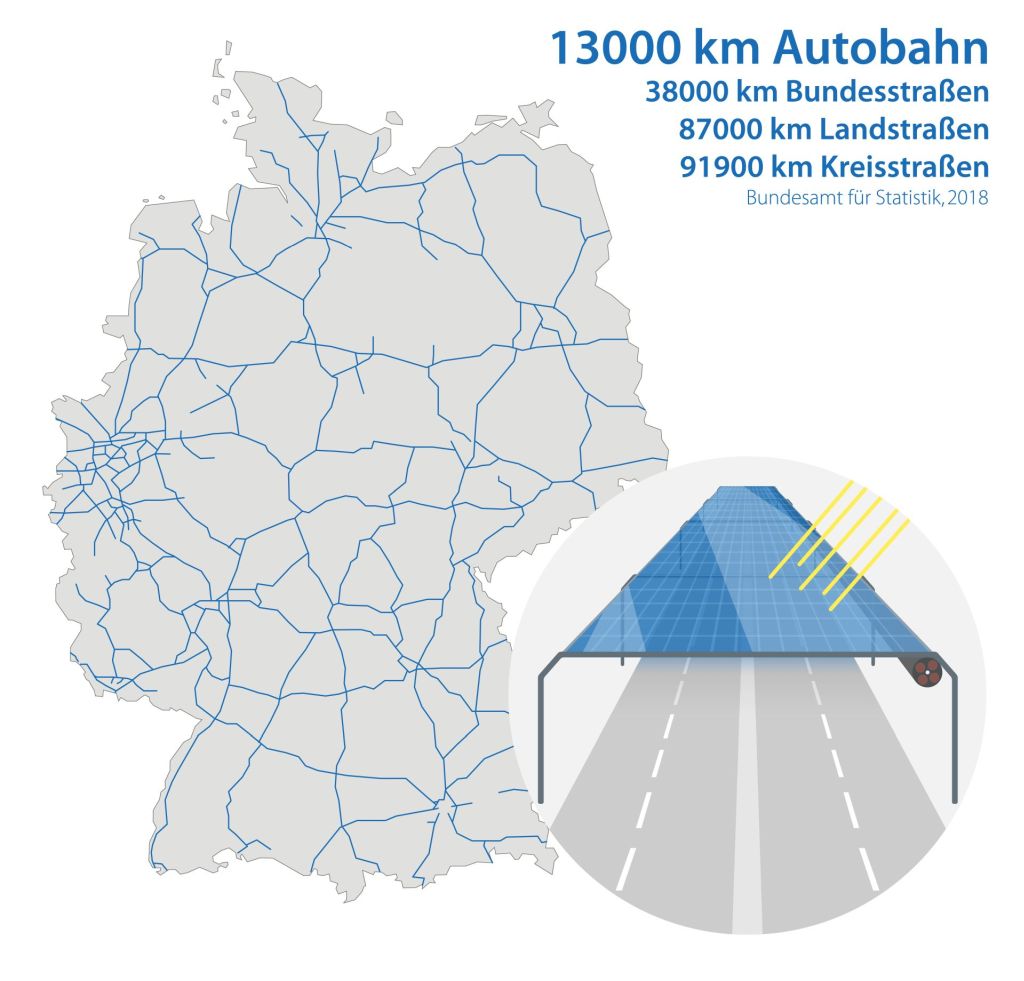

Motorways as solar farms

Berlin, November 2020 - Motorways as solar farms, Matthias Krinke, CEO of pi4, has been recommending this for years! Tens of thousands of kilometers of autobahn cross Germany. A research project is now investigating whether the gigantic areas can be used for solar roofs. The energy yield would be enormous and there would also be other positive effects, such as no additional land consumption and safe ice-free transport in winter without road salt. The quality of the solar modules from Germany can be ensured by the fully automatic testing technology of pi4. Data sheet of the module tester.

Temporary use of robots

Berlin, October 2020 - Temporary use of robots: The company Robozän / Robocene offers its humanoid robots from pi4_robotics GmbH in the sense of a “pay per workforce” as temporary workers, among other things as a concierge or as a sales assistant in an independent mini-factory. The promise: the robot is learned in after 48 hours and can then do its job on its own. Matthias Krinke, Managing Director of Robozän, emphasizes: “The customer has no risk because it is a full-service contract and he only pays when the robot is doing its job. It is the ideal model for customers with no knowledge of robots. If the robot proves itself in everyday life and if the need continues beyond the six months, the robot temporary worker is not infrequently taken over”, that is, bought. The demand is there: According to Krinke, his group of companies with Robozän / Robocene and pi4_robotics GmbH will probably make 90% of sales with RaaS in 2022. https://www.maschinenmarkt.vogel.de (German).

Understanding robots

Berlin, October 2020 - pi4, who understand robots: Concept, engineering, production and programming of robot applications and image processing with robots from manufacturers pi4_robotics, Universal Robots, Epson, Fanuc, Kuka and grippers from Robotiq and OnRobot.

24/7 corona tests with robots

Berlin, April 2020 - 24/7 corona tests with robots: No risk of infection for staff and travelers, fast and inexpensive tests without waiting times. The new workerbot has been expanded to include a reader for health cards, sample handling and a notification function via encrypted email or cloud.

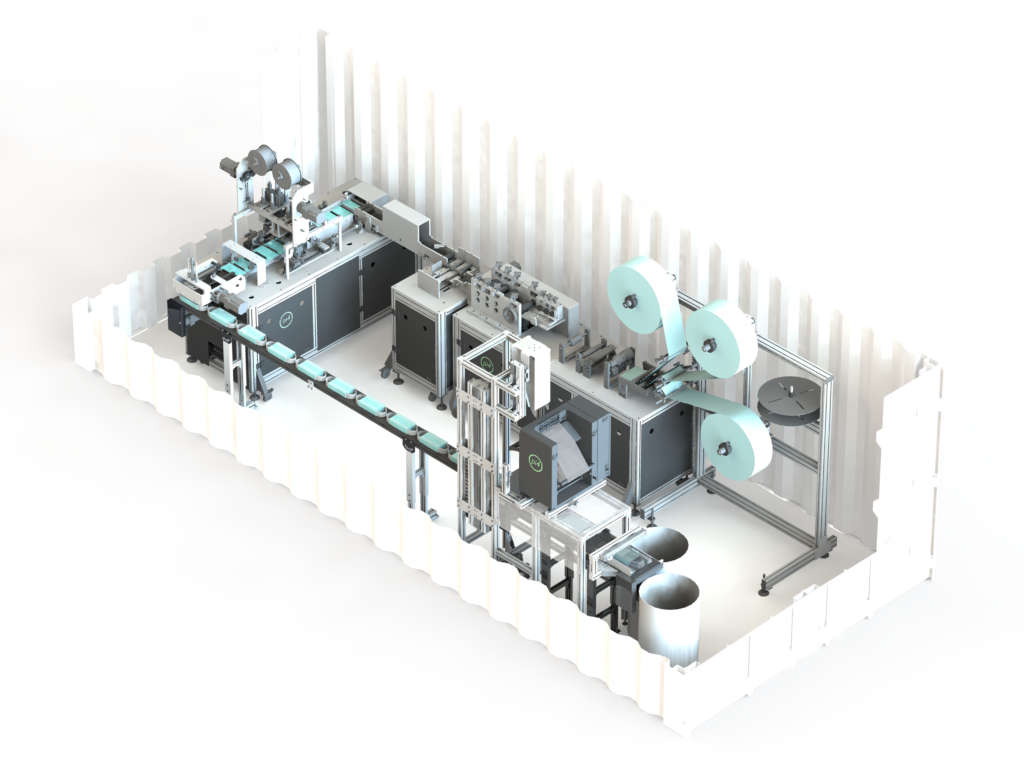

Face-mask dilemma solved: Masks from here, for all, immediately

Berlin, April 27, 2020 - A small robotic factory quickly produces and sells masks locally.

There is an urgent need for something to change in production of the coveted mouth-and-nose (oronasal) protection masks. Two Berlin companies have acted early and started unusual cooperation. The result: the masks can now be produced, packaged and offered exactly where they are needed. Fast, inexpensive, space-saving and completely automatically. The RespiratorBot could supply the whole of Germany. The first mini-factories will be delivered already in May.

Today, when you say “factory”, you usually mean huge halls, somewhere far away from the lives of the people who need the product in question. This is precisely what the Corona crisis has made into a problem: when demand rises sharply, global supply chains appear less resilient - and are prone to corruption. In the case of medical protective equipment, the failure of a delivery can cost human lives.

Enter: pi4_robotics and Mikron Berlin. “Together, our companies have everything we need to solve this problem”, says Matthias Krinke, Managing Director of pi4_robotics. The company has recently caused a sensation in the retail trade: it is the only manufacturer of robots in the world that manufactures products independently and sells them directly, in its own worker robot kiosk, around the clock. Mikron Berlin, in turn, specializes in manufacturing systems for large quantities. “We wanted to get a fast production line for mouth-and-nose protection masks into as small an area as possible”, says Nils Rödel, Managing Director at Mikron Berlin. “In addition, the system should be absolutely easy to maintain and adjust”.

The result is the RespiratorBot: A mini-factory complete with sales staff - but almost entirely without human labor. It fits into a normal sea freight container in which it can be both transported and set up. For example, in front of a hospital, next to a shopping center, behind a school. The integrated air conditioning system with an air purification filter enables production even in places with high levels of virus contamination. The system independently reports material requirements and quantities via the Cloud. This keeps the use of people and thus the risk of infection to a low level.

Because transport routes are eliminated, the end product becomes cheaper. This is especially true for the option of selling the masks to individual end users right at the place of production. Depending on the set-up, the system can offer packs of 10 or individual masks - packed cleanly in welded bags and, if desired, in printed bags and boxes. Of course, all masks have a nose clip and a center layer of special, particularly fine meltblown material. The customer can certify them as medical products. A single RespiratorBot produces more than two million units per month. “We have calculated from official statistics that medical personnel in Germany need at least 50 million mouth-and-nose protection masks per month”, says Nils Rödel from Mikron. “We could cover this demand with just 25 containers”. And Matthias Krinke adds: “Since we already have a nationwide mouth protection obligation for the public, the RespiratorBot with its direct sale is particularly well suited to supply people close to their daily life”.

Robotics4Retail: Robots help the corona rules to disinfect hands and limit the number of customers to comply with the retail trade.

Berlin, April 2020 - Robotics4Retail: Robots help to comply with the corona rules of hand disinfection and limiting the number of customers in retail. Our robot IOSY acts as a friendly receptionist who monitors and regulates the number of customers in the store. During the waiting period, the robot motivates and instructs customers on how to disinfect their hands. Retailers can buy or rent the robots at an affordable price. The robots are available from stock.

Production facility for 30 million respirators per year

Berlin, April 2020 - Made by pi4 Berlin: Production facility for 30 million respirators per year. Delivery time currently 2 months. The integration in the sea container enables production directly at the point of need. Optionally, a fully automated factory outlet can be integrated.

Concierge robots protect your employees from risks

Berlin, March 2020 - The Concierge Robots greet your guests politely, professionally, always reliably and in a good mood; check identity (face recognition and comparison with ID card data); check whether the visitor has a fever (non-contact temperature measurement); the visitor has an appointment; instruct the visitor in the safety, hygiene and data protection guidelines; inform the host and motivate the visitor to hand disinfect in the waiting area.

“Germany’s most innovative company”

Berlin, March 2020 - Capital 03/20: “Germany’s most innovative company”. They create new things and change their industries: that’s pi4. Many talk about progress. But which companies really create new things and also implement the ideas? With the data analysts from Statista, the business magazine Capital has identified pi4_robotics GmbH as one of the most innovative mechanical engineering companies in Germany.

Service Robotics Live!

Berlin, October 2019 - “Alex Workerbot” helps out the service stuff at Conrad’s in Berlin, Schöneberg.