Workerbot3 - dual arm robot

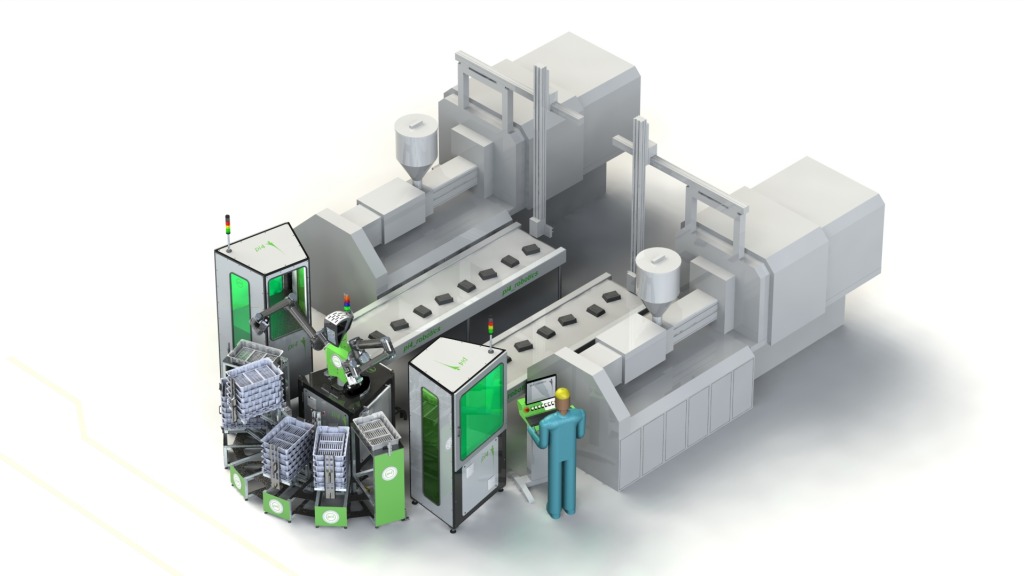

The new generation of the Workerbot3 is here:

“Seeing hands” make it more flexible than ever before. It can recognize the position of parts and make corrections itself.

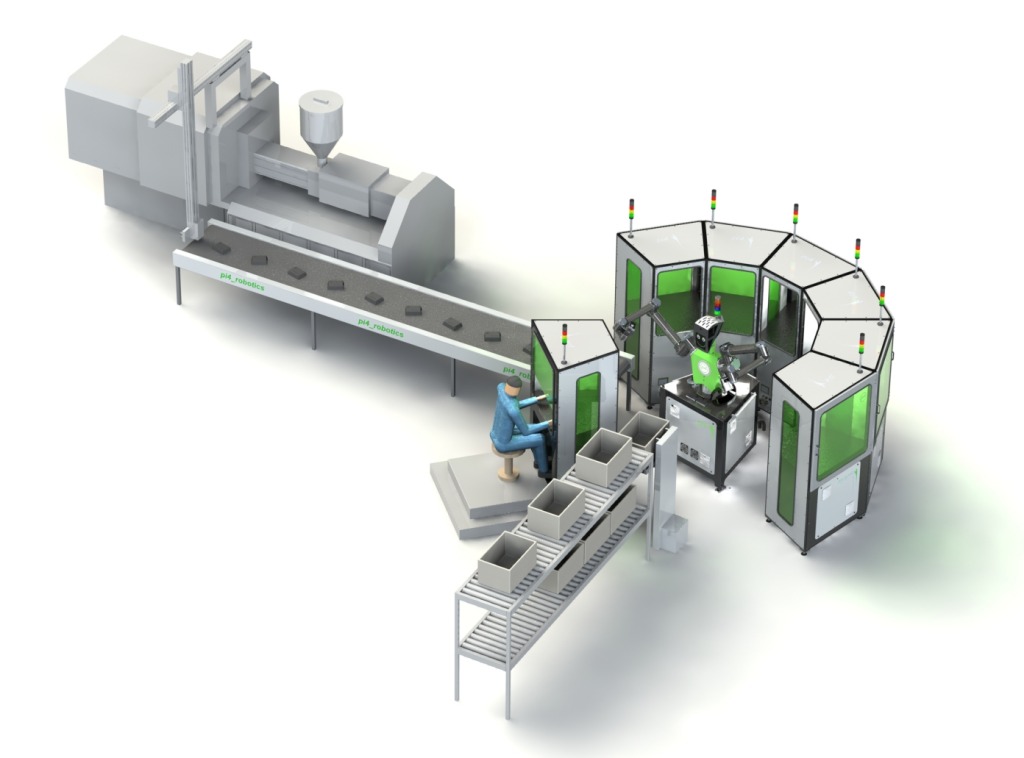

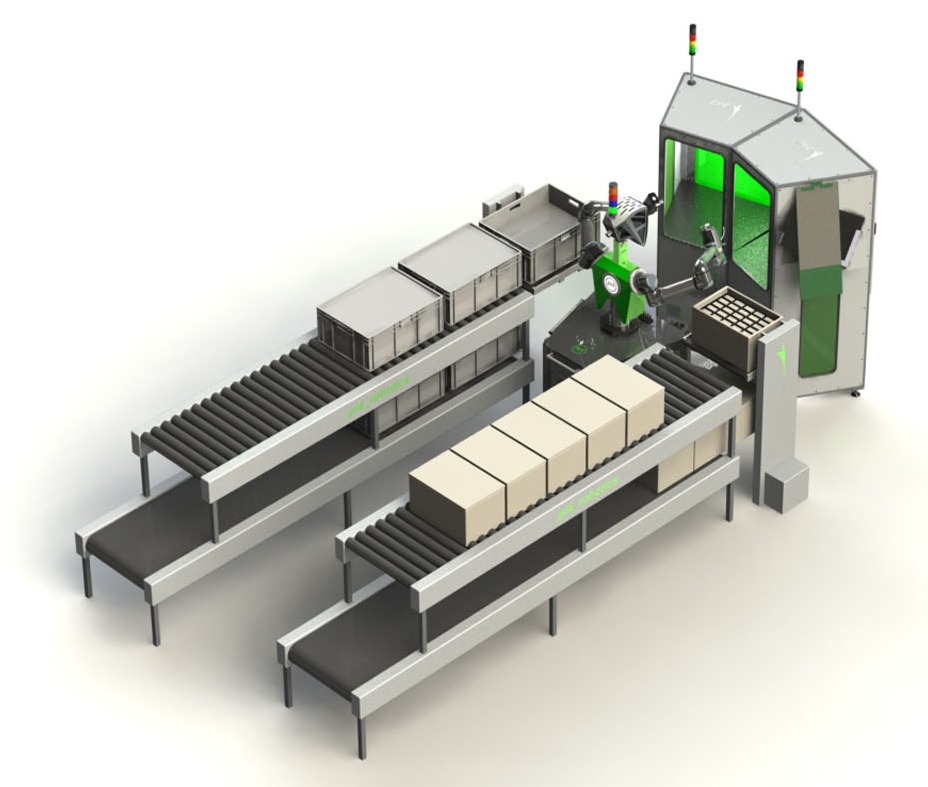

The increased payload of 10 kg per arm, its arm length of 1.3 m and an additional axis of rotation in the waist enable the Workerbot3 to independently load and unload its workstation and the autonomous parts supply.

It has integrated safety technology of the highest category, for connecting safety light grids, safety fence monitoring or laser scanners.

The entire family of peripherals can be connected via the integrated pi4-bus, such as inspection and buffer systems. The humanoid factory worker, immediately deployable, mobile and flexible through the simplest configuration of new tasks.

The Workerbot3 is the answer to the requirements you have defined for highly flexible manufacturing and thus for today’s factory automation: ever shorter product life cycles with increased product variety and - as a result - smaller quantities. In addition, fluctuations in the number of units are becoming increasingly cyclical, which make medium and long-term planning increasingly difficult.

The use of the Workerbot3 can make cost-effective production in Europe possible. Europe. Furthermore, the robot combines the high degree of flexibility with precision and integrated automatic monitoring, thus ensuring consistent product quality.

Features

- human appearance and face for easy communication

- Arm length 1300mm or 850mm

- Load capacity 10kg or 5kg per arm

- optional torso rotation for upper body movement

- different grippers possible

- cameras and image processing for part recognition

- integrated safety system

- Software pi4_control for easy control